High Performance Building Envelopes – IR Scanning to create an Integrated Design and Construction Feedback Loop

InfraMation 2015 Application Paper Submission

Matt Cable

DIALOG

ABSTRACT

Designing and constructing a high-performance building envelope requires careful detailing and considers many factors such as energy efficiency, natural light and materials performance. Designers turn over detailed construction documents to a construction team who do their best to construct what designers convey - but does this process work?

The extra step of building envelope thermographic imaging completed the Integrated Design Process which DIALOG is using on multiple projects across Canada - taking our integrated nature of energy modelers, architects, structural engineers and contract admin to the forefront of integrated design. Sharing this knowledge internally with DIALOG employees has helped our firm create better high performance buildings, completing the knowledge loop and improving both design and construction on our projects. It has ensured that old details and specifications are removed and updated based on feedback from the IR scans.

What did we learn from looking at this building and what lessons can we apply when we design new projects? This session brings the whole building industry to learn together about building envelope performance, and better design and construction practices. Sharing this knowledge can help owners, operators and anyone in the building industry to create higher performing buildings.

INTRODUCTION – HIGH PERFORMANCE BUILDINGS

More and more on new projects clients are demanding improved energy performance, environmental quality, durability, cost effectiveness and lowered environmental impact. High performance buildings significantly outperform minimum standards in all these areas. The building envelope contributes highly to these items – insulation, air tightness, daylight, views, ventilation and water/moisture management. Design and construction for high performance requires a better method of project delivery.

Generally speaking high performance building enclosures are highly insulated, air tight, with access to daylight and views to the outside. Water and moisture management are a must and where applicable enclosures may have the ability to provide natural ventilation.

INTEGRATED DESIGN PROCESS

The integrated design process (IDP) promotes enhanced collaboration, communication and knowledge sharing between disciplines. Higher performance in buildings is achieved more organically using this model for project delivery.

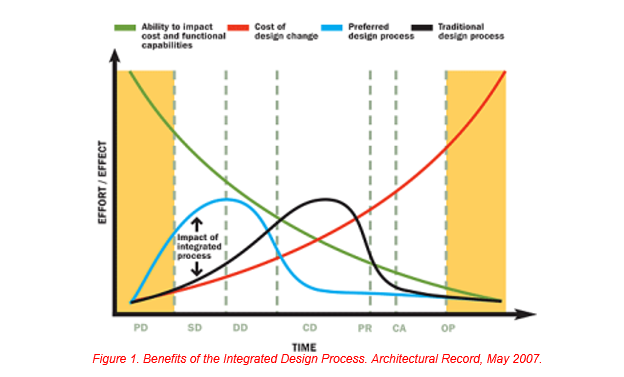

The design team focusses on setting and achieving challenging targets rather than following steps. It fosters enhanced collaboration, communication and knowledge sharing and considers all stages of building lifecycle – not just linear design process. All the expertise is brought to the table early on - stakeholders (finance, O&M, occupants), engineers, contractor, costing, commissioning, energy modeler, etc. As demonstrated by the following figure shifting efforts forward achieves better solutions earlier and cheaper. Less time and money is spent on contract documents and change notices.

THERMAL SCANNING FOR NEW CONSTRUCTION

In the standard model you may typically see that the owner hires a third party consultant, they do a scan and write a report which gets emailed to architect, engineers and contractor. This is certainly better than not doing a scan at all, but there appears to be a lot of room for improvement. It’s a retro-active approach where the scan identifies problems when it’s likely too late to fix them. The building owner doesn’t get the most value from the scan – they just get a report identifying the biggest problems.

Bringing IR into the IDP and allowing the thermographer to be part of the team from the beginning maximizes the value of this scan. Designers get input on what works – continuous insulation, air tightness, water sealing, etc. and contractors are provided clear expectations and best practices for installation. This also allows the thermographer a better expectation of what they will be looking at and where focus of the study should be aimed at. Any possible issues can be identified years, months, and weeks before it’s too late and the owner gets a high performance envelope – not just a fix for the worst problems. Finally this knowledge is built throughout the team and everyone involved in the process gains experience building higher performance buildings.

At DIALOG integrated design is a big part of who we are and it’s our belief that every building should be high performance. Our building science team has two cameras, three certified thermographers and IR scanning in 4 offices across Canada. DIALOG includes IR scanning in the specs and construction meetings. The contractor understands the expectation and since the IR professional is part of the team – they know the project. Envelope performance goals are set in DD/CD before details & materials are chosen and envelope design workshops share knowledge across project teams, offices and disciplines.

This process started with imaging 4 buildings, 1 in each city (Toronto, Calgary, Edmonton and Vancouver) and creating a workshop with the design teams in each dedicated studio. An introduction to the thermal imaging was provided to the participants, the construction photos, details, specs and images from the site where shared and the problem solving began. The outcome of these workshops was exactly as expected – knowledge sharing between disciplines, identification of weak spots in details and specs and a greater appreciation for the construction of buildings closing the design feedback loop.

CASE STUDY 1 – HEALTHCARE FACILITY

The Greenwood clinic is the first Care Delivery Unit (CDU) to be designed to LEED standards as the Canadian Forces Health Services rolls out its redesigned primary care model across all CF clinics over the next few years. The Canadian Forces has identified the need to update or construct new health care clinics across its bases, and as a result CFB Greenwood serves as a prototype to implement a sustainable and energy-saving design approach that can serve as a model for future CDUs.

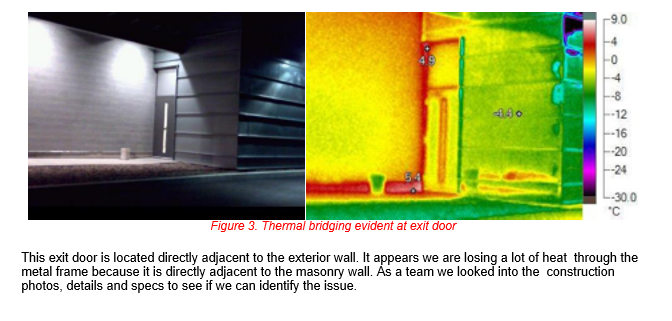

The building has a highly-thermal resistant building envelope, including an R38 roof, R15 polystyrene walls and glazing U-values of 0.44 btu/ft²F. There were some features of the building that were identified as weak performing areas. One example of this was thermal bridging at a door opening. Thermal bridging is visible at the door frame as well as at the floor slab.

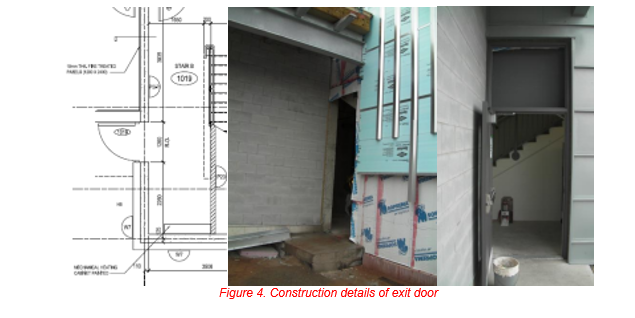

This exit door is located directly adjacent to the exterior wall. It appears we are losing a lot of heat through the metal frame because it is directly adjacent to the masonry wall. As a team we looked into the construction photos, details and specs to see if we can identify the issue.

It is obvious the door frame connects directly to the masonry wall, and the two conductors are side-by side. We can’t insulate between them or provide a proper air seal. The detail communicates to the contractor how the door is to be located. Lesson learned – where possible, move the metal door frame away from the wall to improve insulation and air barrier. Add details to communicate the right method for installation.

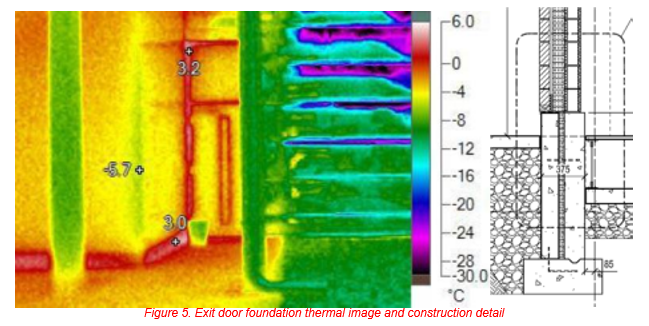

As for the floor slab, it appears to be uninsulated from the thermal images.

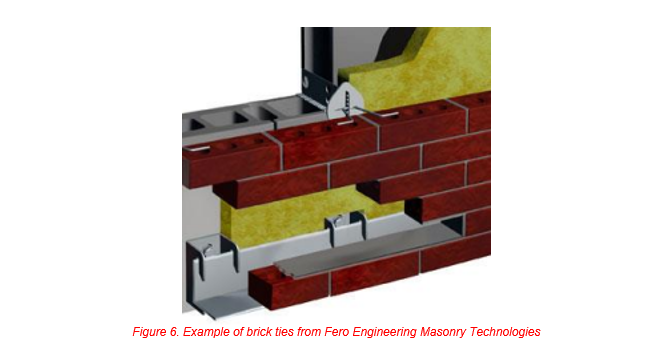

The detail shows that the foundation wall is exposed and minimally insulated causing losses heat along the perimeter of the building. With only 1-2 inches of insulation in the foundation, R10 is good enough for below grade but not for a wall. Insulation installed inside the concrete is difficult to verify -- is it continuous, is it even there? If an inspection is completed days after a foundation is poured it is tough to verify. A way of mitigating this issue may be to use brick ties (shown in the figure below) to suspend the brick allowing for mostly continuous insulation in behind the lintels. This would allow the wall insulation to come down to grade decreasing the thermal conductivity shown in the thermal image above.

This analysis was completed on other areas of the building completing the feedback loop for building design.

LESSONS LEARNED

∙ High performance buildings need high performance envelopes that manage air, water and heat. ∙ The IDP facilitates higher levels of performance through enhanced collaboration and communication.

∙ IR scanning is a cost-effective method for evaluating envelope performance ∙ Start early! Get your building science expert involved as part of your IDP.

∙ Ensure that the IR scan is clearly identified in the construction documents and meetings. ∙ Use the IR scan to show that we got it right.

ABOUT THE AUTHOR

Matt is a Sustainability Consultant and Level 2 Certified Thermographer at DIALOG, an integrated design firm where architects and engineers collaborate to make some of Canada’s greenest projects.

Matt currently has over seven years of professional experience in sustainable design and building energy analysis. Since graduating with his Masters in Computational Fluid Dynamics at Queen’s University, Matt has specialized in low-energy solutions and building science is leveraged by his experience and certifications in Thermography Certification (Level 2), Measurement and Verification (Certified M&V Professional), and Green House Gas Inventory, Accounting and Reporting. He created DIALOG’s Carbon Action Plan and maintains DIALOG’s Carbon Neutrality.

Matt recently completed a 5-year energy conservation and demand management plan for the entire Centennial College and Northern College Campuses which included a full thermographic assessment of the building portfolio.