Three Ways the Pest Professional Can Use Infrared Thermography

InfraMation 2004 Application Paper Submission

Bart Bruni

Spectrum Infrared Building Solutions

ABSTRACT

In this paper I will share some of my experiences as owner and founder of Bestec Exterminators and Spectrum Infrared Building Solutions, Hallandale Beach, Florida. Our business is the remediation of exotic insects, and we have developed and use thermography in termite and pest inspections as well as in pest and termite remediation. Bestec is a chemical industry cooperator, and we have been chosen to assist in major research and development for soil studies and termite efficacy studies conducted by organizations including Bayer Corporation, BASF, FMC, Syngenta Corporation, University of Florida and many others.

INTRODUCTION

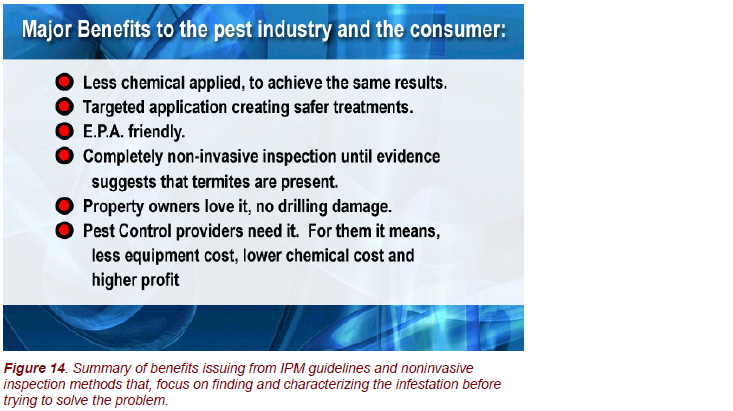

Pest and termite practices recommended by the National Pest Control Association are called “Integrated Pest Management” or IPM. The concept is simple: to find the nest and eliminate it, as opposed to simply spreading insecticide in hope that pests enter the treated area. IPM addresses safer treatments with better results. The problem is that this is easer said that done.

One of our most effective tools is infrared (IR) imaging. IR imaging has enhanced the standard of IPM in several dramatic ways:

- It takes less inspection time.

- An IR inspection yields immediate information quickly.

- Is an aid in locating and treating above ground subterranean nests.

- Provides data that can help determine the extent of damage.

- IR plays a major role in post treatment quality control.

UNDERSTANDING THE ENEMY

Termites do more damage in the United States each year than fires and storms combined. They are a threat to property owners across 70 percent of the world and in every part of the United States with the exception of Alaska.

The types of termites that we have in North America include: Drywood, Subterranean, Dampwood, and Arboreal termites. Each type has several varieties, and some types of termites are more destructive than others. The most destructive types are Subterranean and Arboreal termites.

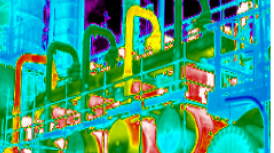

The most destructive termite species in the world is the Subterranean Formosan termite Coptotermes formosanus (see Figure 1). Formosan termites are indigenous to China Imported to the U.S. in the early 1980s, and they thrive in even a hardy, rocky environment. Nature has provided this single termite species with the ability to secrete an acid that dissolves concrete, steel, lead, copper, glass, tile, etc. to get to wood. One colony can consume as much as three lbs. of wood per day and often more if that one colony is attacking a structure. Here are some disturbing facts. The life expectancy for a 2,000 square foot home, CBS constructed, under siege from this termite, left uncorrected, would be approximately 24 months. They will literally eat you out of house and home.

Last year in Broward County Florida, Formosan termites did hundreds of millions of dollars in uninsurable property damage. When you consider that the Formosan termite infests a very small percentage of Broward County, it is a terrifying amount of liability for property owners to bear. Formosan termites have infested the entire southern tip of the U.S., causing billions of dollars in damage each year. Formosan termites will nest above ground in structures, aggressively taking advantage of moisture sources such as condensing A/C lines, roof leaks, etc. At this point, these termites no longer need ground contact for moisture, and are essentially unaffected by ground treatment methods

LOCATING INFESTATIONS

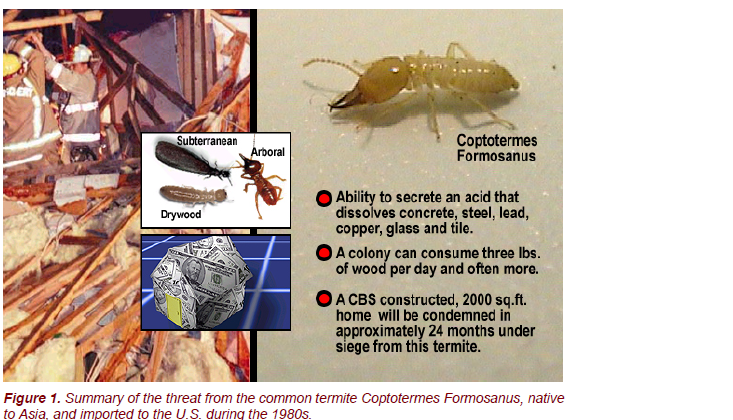

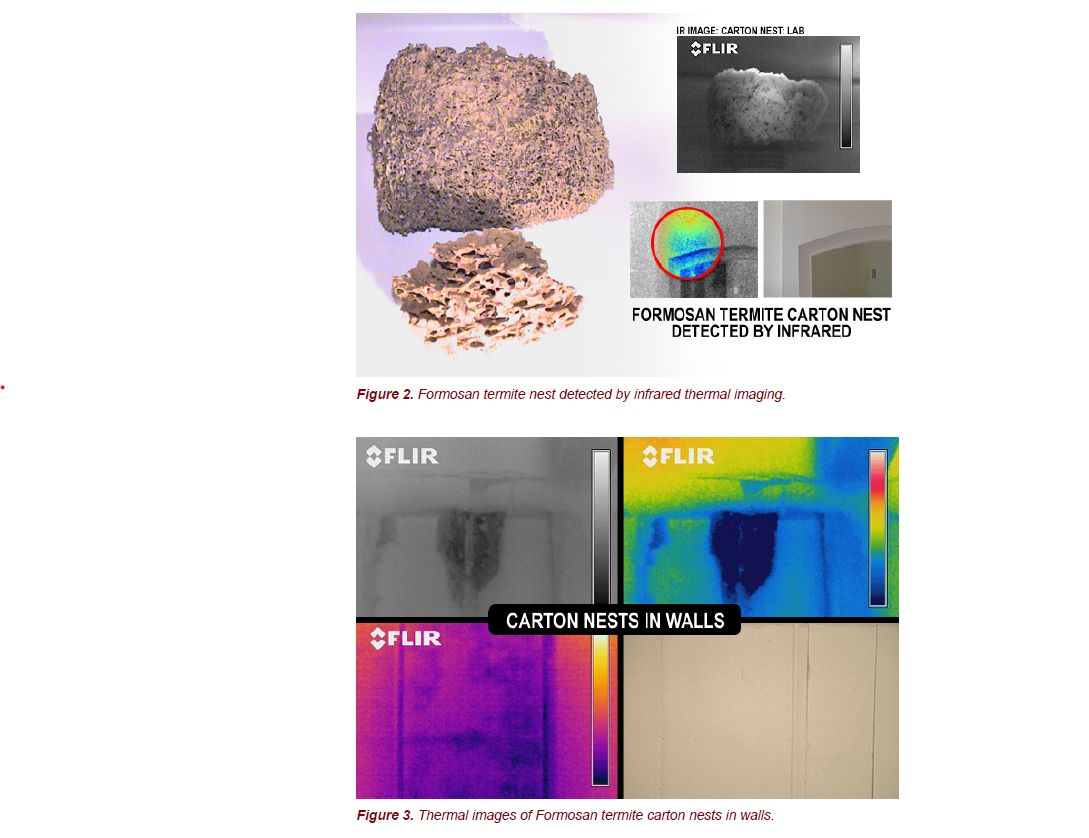

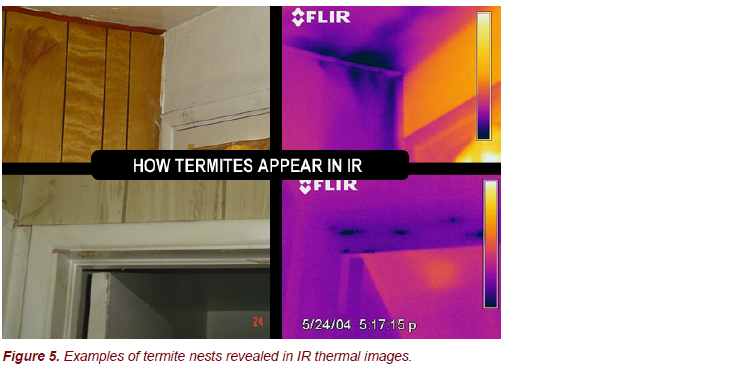

IR thermal imaging, or thermography, is effective in locating and treating above ground nesting sites called carton nests. Finding these nests is a difficult task and critical for successful treatment. If they are not found, the treatment will surely fail. Figure 2 shows a Formosan termite nest detected by infrared thermal imaging under laboratory conditions. Figure 3 shows additional examples of carton nests in walls. As you can see, carton nests come in all sizes and shapes. The first set of images show these termites took advantage of an above ground moisture source. The set below shows that they nest above ground, with no above ground moisture source. In this case, the termites are still using the ground as a moisture source. The IR images during this presentation are taken with two types of cameras; The FLIR ThermaCAM E series camera with a 22 mm lens, and an ISI Insight with a 20 mm lens.

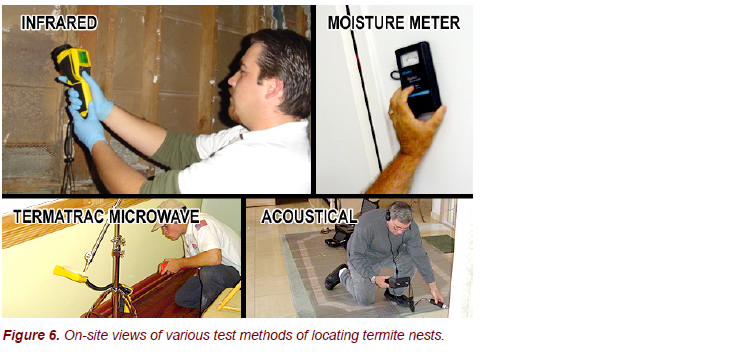

Referring to Figure 4, in addition to the two types of cameras, we also use Tracker the termite detection dog, a magnifying glass, an aspirator to collect termite DNA samples, vials of alcohol, monitoring stations to collect termites, compressed air, laptop computer, flash lamp, a cordless drill and assorted lights, non-intrusive moisture meter, density detector, digital camcorder, fiber optic scope, Terma-trac microwave detector, ultraviolet light and pen, Kestrel thermometer, high power ocular lens, IR camera mirrors, and small hand tools. There are many other tools used in the pest control industry, but not relative to an infrared pest inspection.

The carton nest is moist and evaporating as well as condensing in the concealed space that contains the carton. The termites are metabolizing, creating heat and moisture, which are vital for their existence. Termites behavior is directly associated with temperature and relative humidity.

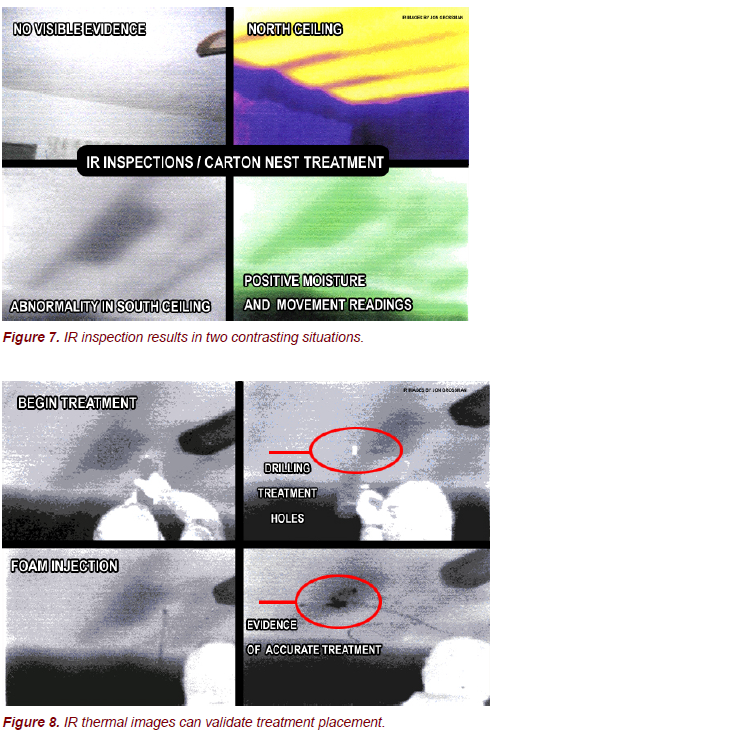

The process works as follows (see Figures 6 and 7). First a visual inspection by an accredited pest professional must take place of the attic, crawl space, interior and exterior of the structure. This is followed by an IR scan of the interior walls, floor, and ceiling, inside and outside. If anomalies are found, IR images and photos are then taken of the suspect area and we check with a moisture meter. If the results are twenty percent or more, then a microwave test which detects movement in objects is performed. To verify active termites in flat roofing, and flooring quickly and accurately, “Tracker” the certified termite detection dog is the best choice. Acoustical testing will sometimes be used to reveal carton nests, all of which are non-destructive, non-obtrusive methods. At this point, moisture and movement have been detected, we can hear the problem and Tracker can smell the termites, then we request permission from our client to begin destructive inspection methods. Next, we intrude upon the site with a fiberoptic scope for proof positive that live termites are present, and then treat or physically remove the nests.

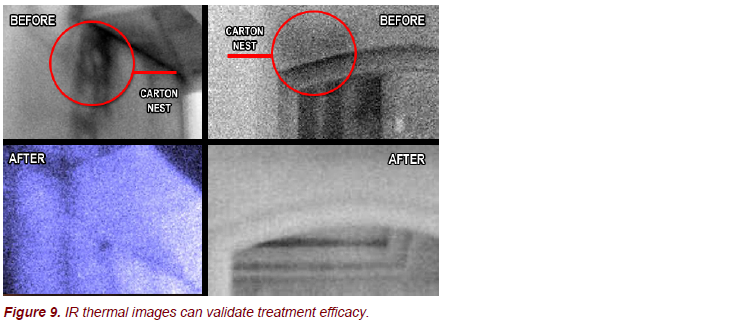

Active thermography plays a big role in placing the chemicals precisely, as shown in Figures 8 and in assessing the results, as shown in Figure 9. Hot or cold water is used to mix the chemical of choice, thus we can record and track the material as we inject it into the nest or treatment areas. The benefits are less material used, with increased accuracy in our application as well as providing valuable documentation.

POST-TREATMENT

Post treatment, in my opinion, is where infrared has the most impact on pest management. The current criteria used for a termite inspection takes a long time to perform, and damage will be necessary during the inspection to disclose live termite activity (see Figure 10). I have successfully performed inspections using this process for 18 years. Incorporating IR reduces the overall time to complete the inspection, reduces the amount of property damage, and summarily increases productivity and profit margins.

Infrared thermal imaging has improved my inspections and increased profits by facilitating thorough documentation with pre and post treatment IR images. This evidence provides clients with visual proof that the treatment was successful.

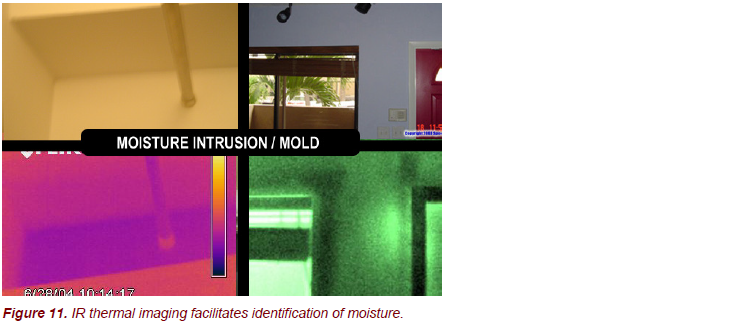

INSPECTING FOR MOISTURE

Another example is easier identification of roofing or plumbing leaks and general moisture intrusion, which will increase risk of re-infestation of Subterranean termites and other insect infestations such as ants, roaches, rodents, and silverfish. As pest professionals, if we know that a structure is infestation-free above ground, and we can define moist areas vital to insect existence and recommend how the property owner can correct them, then we have provided a positive result. By doing so, we have reduced our liability as a company through IR documentation. IR images in termite reports help promote client awareness so they may be able to contribute to the overall results of their termite treatment. Consider that if a treatment fails or re-infestation occurs, it can cost the property owner thousands of dollars per week in wood damage. Clients are usually quick to respond to our recommendations.

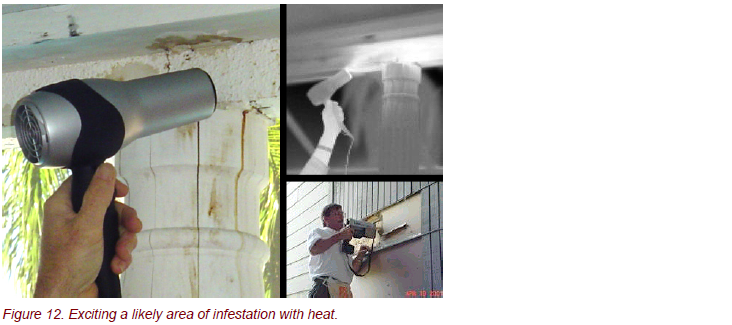

In the past, non-destructive methods of detecting termite damage, not visible to sight or touch, have been limited. Through the use of active thermography we sometimes can provide our clients with more information about the amount of damage the infestation has caused. When IR is used in conjunction with a resistograph, it has created a very fast and effective method to assess and record termite and pest damage. The resistograph is a tool that looks like a cordless drill. It works by drilling a tiny hole into wood and records the density on a graphic printout. After locating the suspect areas of damage, we excite the area with heat (see Figure 12), and as the target cools down, the IR images can be captured. Then the resistograph is used to test the density of the wood. With the use of IR in this type of inspection productivity will increase and the inspection will be considerably less destructive.

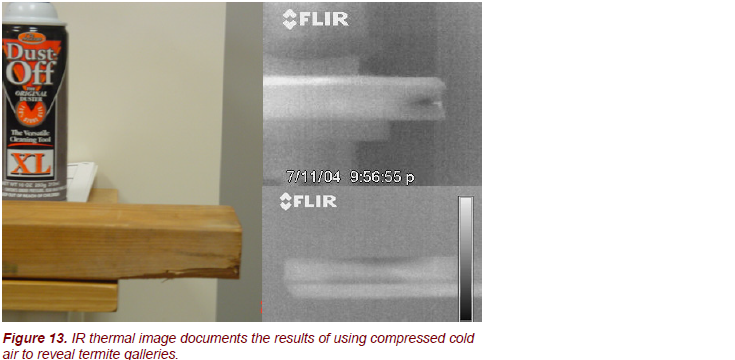

Another method used to determine Drywood termite, wood destroying beetle, and carpenter ant damage, that has shown superior results, is to use compressed air to create cool thermal conditions. It starts by inspecting for exit holes that termites make in building materials, and injecting cold compressed air directly into them. This allows the detection of the entire area of wood that the pests have carved galleries into. The photo shown in Figure 13 shows a seemly unaffected solid two-by-four. The first IR image indicates where compressed air was injected into a tiny exit hole the termite created. The second IR image shows the opposite side of the same wood thus showing the damage created by the termites.

SUMMARY AND OUTLOOK

Pest control industry regulations to integrate IR and termite DNA testing, regarding pest management, and developing cameras specifically for pest management, are some challenges that the IR community and the pest industry will be facing together.

Qualitative thermography is the best practice for IPM professionals. However, in termite inspections, often times you are looking at a subject that has never been inspected using an IR camera, thus not much to compare your anomaly with. I feel that it would be of great value to both industries, to have a special classification for IPM thermographers.

REGULATION

Challenges remain for regulation of the pest industry—for example, requiring a minimum of holding a Level 1 Thermographer Certification to provide IR termite inspections to the public. There should be regulations in place requiring an IPM thermographer to be a State licensed pest inspector. In addition, the inspector should be required to work directly with a state-licensed pest control operator well versed in the target pests involved.

In the near future inspection will be the broadest part of the treatment pyramid, thus creating new positions for IPM thermographers and non destructive inspectors in termite and pest companies everywhere.

NEW METHODOLOGY

Opportunities for IR thermography and other high tech devices that help detect termites have never been better, and is an asset to the future of the termite and pest industry. We are fortunate to have been chosen to be a part of Bayer Environmental Sciences, and the University of Florida soil studies since 1998, which spawned new treatment specification theories, applications, and new ways to utilize good chemistry. For example, incorporating termite DNA sampling as a part of the treatment specification may soon be the future of termite remediation. Past studies have proven that control of Subterranean termites can be achieved without extensive drilling into the foundation; however early studies had mixed results. The problem was the inspections that occurred subsequent to the treatment were not accurate enough to detect live termites prior to damage.

This treatment method, loosely referred to in the termite industry as “trench and drench,” is not yet a standard treatment strategy for the remediation of Subterranean termites. However, it does have the potential of becoming the standard in the near future. Recent termite DNA testing provides a new look at the trench and drench theory. Future specifications may require the technician to trench all exposed soil areas that have contact with the foundation of the structure, install monitoring stations around the perimeter of the infested structure to locate termites for DNA sampling, and to locate active sites called subplots, inside and /or outside the structure. Post treatment inspections would be planned to take place in 7, 14 and 30 days after treatment, following with inspections in increments of 3, 6, and 12 months, then every 90 days thereafter.

This frequency contrasts with the once per year inspection that is currently a termite industry standard, and can eliminate some of the “standard” destructive and expensive practices for Subterranean corrections, such as: drilling and injecting all adjoining slabs to the foundation, expansion joints, soil pipes in bathrooms, void areas in each concrete block around the perimeter of the structure, and drilling in flooring. In the event termites are active in such areas, treatment would have to be applied 5 feet on each side of the infested site. The benefit to this treatment approach is a whole lot less drilling.

NEW IR CAMERAS

Other challenges for the IR industry are developing specific hand held cameras for the termite industry. Termite specific cameras would need high quality detectors capable of detecting anomalies in near ambient temperatures. They will need to be lightweight. They would only require average to good quality optics, and the proper field of vision necessary for termite inspections, as well as priced to meet the consumer budget. There is and will continue to be a huge market waiting to be tapped in the pest industry for IR camera manufactures.

With the proper equipment and training, termite service providers can learn that IR technology has proven to have benefits. Examples of these kind of benefits are, increase product marketability, professional cutting edge company image, reduces liability, creates visual proof of treatment success, reduces inspection time, locks in renewal fees, creates less call backs, and less material used. This also creates a new income stream for inspections other than for pest, such as moisture surveys for roofing and mold all of which will increase profits, and company net worth.

I know in my company I was able to recuperate my investment into IR in less than six months. This was verifiable by my accountant, which was a simple profit and loss accounting of the above mentioned categories. The biggest challenge presented to the IR industry is for its leaders to interface with the National and State Pest Control Associations, USDA, Department of Consumers Services, and major chemical companies. The insurance carriers for the pest control industry have been the first to endorse the concept of using accurate nondestructive inspection methods. They clearly see the benefits of detecting damage, live infestations, and conducive conditions that are relative to treatment.

In this scenario the pest professional’s documentation would be the broadest part of a Subterranean termite treatment, as opposed to chemical application being the main thrust. This can only lead to safer and more successful treatments for consumers, as well as new and exciting market places, for both the IR and Pest Control industries.

I am certain that in the future, IR in the pest control industry will be widely used, and provide assistance for pest control challenges not yet mastered.