Application of Mid-Wave and Long-Wave IR Imaging in Large-Scale Rack-Storage Fires

InfraMation 2013 Application Paper Submission

Jaap de Vries, Ph.D.

FM Global

ABSTRACT

This paper discusses the use of a mid-wave and a long-wave infrared camera for the study of large-scale rack-storage fires. Broad spectral surface properties of both virgin (surfaces unaffected by the fire) and charred corrugated paperboard, often seen during warehouse fires, were characterized using separate Fourier Transform Infrared Spectroscopy (FTIR) analysis. Custom calibration of a long-wave IR camera showed that the effective temperature range could be extended to cover temperatures exceeding 1,000°C. Images obtained from a recent study on the fire dynamics of lithium-ion batteries were used to illustrate the effectiveness of IR thermography. Visible HD footage was registered and fused with LWIR thermographic images and shown to improve contrast and feature recognition.

INTRODUCTION

Understanding the science of warehouse fire dynamics is anything but simple. At the Fire Technology Laboratory, FM Global continues to advance the understanding of how materials and fire behave. In fact, spanning 10,033-m2 (108,000-ft2) FM Global's Fire Technology Laboratory is the centerpiece of the Research Campus, located in West Glocester, Rhode Island, USA and the largest facility of its type in the world.

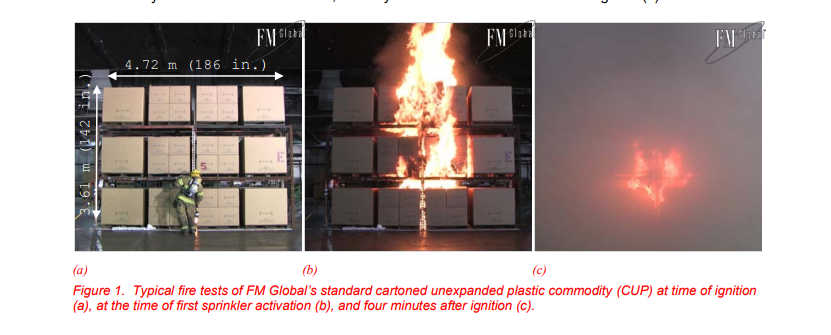

Quantitative temperature measurements of large-scale fires are of key interest to FM Global’s researchers and engineers. Full-scale fire testing, particularly full-scale sprinkler testing is currently the primary method to develop loss prevention recommendations; however, during many full-scale sprinklered tests, steam and smoke, as a result from suppression water, obscure the visibility of the flame. An example of this is shown in Figures 1(a)-(c). Figure 1(a) shows a representative rack-storage setup of FM Global’s standard cartoned unexpanded plastic commodity (CUP) in a 2 x 4 x 3-tier-high array at the time of ignition. Approximately two minutes into the test, the first sprinkler activates, which is shown in Figure 1(b). After sprinkler activation, thick steam and smoke layers develop, which surround the test array. Four minutes into the test, visibility is all but obscured as seen in Figure 1(c).

Using IR cameras to see through hot gaseous combustion products can be accomplished by using spectral (see-through-flame) band-pass filters, which avoid spectral bands that have significant attenuation due to gas-phase absorption or emission, primarily due to the presence of CO2 and H2O. Uniform interference due to soot particles, however, cannot be avoided using selected band pass filters, and the interference of sooty flames are best minimized when the IR camera’s spectral range covers long wavelengths compared to the average soot particle size.

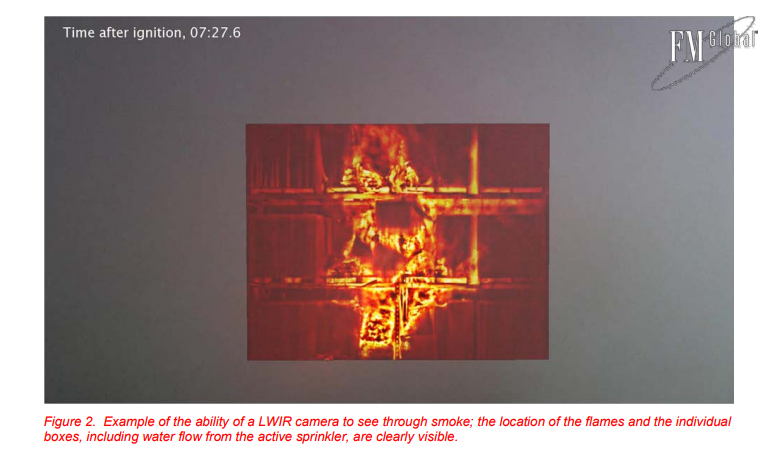

A qualitative example of the ability of a LWIR camera to see through smoke is shown in Figure 2, which has an image from a long-wave IR camera registered and fused with a Vis HD video frame. The details of the fire, including individual rivulets (streaky water flow) formed by the suppression water, are now clearly visible.

BACKGROUND

In general, using infrared (IR) cameras for fire-science applications is a relatively recent phenomenon and has largely focused on the study of wildfire dynamics. Martinez-de Dios [1] used computer vision techniques and infrared images is the 3-5 µm spectral range to measure fire front, flame height, flame inclination angle, and fire base width of forest fires. Similarly, Coen et al. [2] examined the mechanism for the rapid propagation of crown fires during the FROSTFIRE experiment in interior Alaska. Zhou et al. [3] were able to derive flame and plume velocities in wildland fires using an uncooled microbolometer (7.5-13 µm) camera and thermal particle image velocimetry (PIV) algorithms. Spectral characteristics of forest fires important for remote sensing were described by Sun et al. [4], Barcducci et al. [5] and by Melendez et al. [6].

Quantitative IR studies of well-controlled warehouse fires are sparse. Most of the work describing the use of infrared cameras during building fires is qualitative and related to improving firefighting effectiveness or safety. In these studies, the ability of IR cameras to see through smoke or to locate the fire location from outside a building is of interest [7]. For example, the performance characteristics and a standard testing protocol of thermal imaging cameras used by firefighters is given by Amon et al. [8] in a report issues by the National Institute of Standards and Technology (NIST)

The focus and interest for FM Global is to obtain quantitative information with respect to the fire location, fire spread, surface temperatures, and the effectiveness of the sprinkler suppression water. To accomplish these goals, prior knowledge should exist with respect to the spectral emissivity of the burning material. In addition, a thermal imaging camera that can cover the full dynamic range of temperatures should be used. This paper will show how spectral emissivity values of material of interest can be obtained. In addition, maximum temperature range of a long-wave microbolometer camera can be extended by using a simple aperture.

IR CAMERAS

Two different IR cameras are currently used inside FM Global’s Research Campus in West Glocester (RI) to obtain thermographic images, namely:

- FLIR® SC7600 ORION mid-wave IR (MWIR)

- FLIR® SC655 long-wave IR (LWIR)

The FLIR® SC7600 ORION MWIR camera has a rotating filter wheel in front of a 640 x 512-pixel indium antimonide (InSb) photodetector. A 1-5 ∝m sapphire window, a 3.88-3.92 ∝m narrowband filter (to see through flames), and a neutral density (ND = 2, 1%) filter were installed inside the filter housing. The SC7600 is capable of recording 400 frames per second (100 fps/filter); Due to the proximity of this camera to large-scale fires, smoke, steam, and suppression water, the camera was placed inside a stainless steel cylindrical enclosure. The InSb detector’s high sensitivity results in only a narrow temperature band that can be measured at any given time. Even when ‘super-framing’ (combining multiple exposures of a single scene at different integration times) is utilized, a highly dynamic scene with temperatures ranging between 20°C and 1,000+°C cannot be captured in its entirety using this camera.

The FLIR® SC655 LWIR camera has a 640 x 480-pixel uncooled microbolometer thermal detector with a (17 ∝m) pixel resolution sensitive at wavelengths between 7.5 and 13 ∝m. The maximum frame rate of this camera is 50 Hz. The overall temperature range of this camera can be extended by placing an aperture in front of the lens, reducing the incoming IR radiation intensities and raising the usable blackbody temperature range of this camera from a maximum of 650°C to 1,200°C [9]. A separate calibration of the LWIR camera with the aperture placed in front was performed using a blackbody calibration source (Infrared Systems model # 564/301). When properly calibrated, this microbolometer camera allows capturing a full 20°C to 1,200°C temperature range on a single thermograph. The sensitivity of this camera with respect to longer wavelengths make it particularly suitable for seeing through gases mixed with suspended soot particles and small water droplets. All of the discussion in this paper will concentrate on the use of this camera.

SURFACE EMISSIVITIES

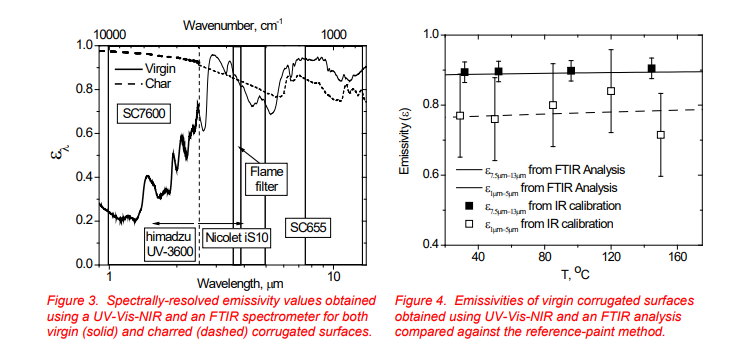

In the case of fires involving cellulosic materials (such as corrugated cardboard boxes often seen in warehouses), the emissivity of both the virgin (surfaces unaffected by the fire) and the charred surfaces needs to be determined. In this study, the surface emissivity was determined via FTIR analysis. A graph of the emissivities from 0.9 to 14 ∝m for both virgin and charred surface conditions is shown in Figure 3. Based on these results, the emissivities over the spectral band for each camera can be calculated using the ratio. Where represents the spectral range of each camera, is the spectral emissivity and is the spectral hemispherical emissive power of a blackbody, better known as Planck’s distribution of emissive power.

In a second method, which uses well-characterized reference paint, the emissivity of corrugated paperboard’s virgin surface was measured in both the mid-wave and long-wave spectral ranges using the IR cameras themselves. To do this, a piece of corrugated paperboard was partly coated with a known (ε = 0.92) high-emissivity paint (Thumalux® solar coating (DP-013-250)) and placed on an electrical heating element. The emissivity was then determined by comparing the measured temperature of the coated and uncoated corrugated material. The emissivities obtained using this method are compared against the emissivities calculated using Eq. 1 and plotted in Figure 4.

The emissivity of virgin material is lower in the mid-IR regime. This means that the emissivity should be set to 0.8 for the FLIR® SC7600 MWIR camera during the initial fire growth. When the surface condition becomes charred, however, the emissivity increases significantly; becoming closer to 0.9. The long-wave IR range shows less wavelength dependency with the emissivity of both the virgin and charred surfaces being approximately 0.9, with the charred emissivity being slightly lower.

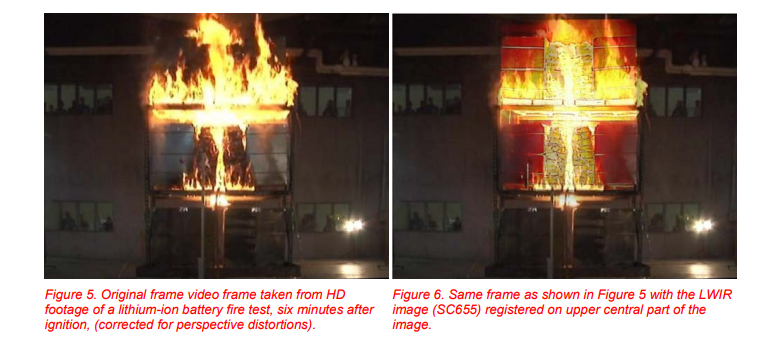

IMAGE ENHANCEMENT AND THE ABILITY TO SEE THROUGH SMOKE

Image registration seeks to align two images taken of the same scene, i.e., registration is the determination of a geometrical transformation that aligns points in one view of an object with corresponding points in another view of that object or another object [10]. Image registration was used to fuse infrared images onto visual images in a study on the hazard posed by lithium-Ion batteries [11]-[12]. In this way, the infrared information can enhance the visual images, adding contrast and temperature information. An example of this is shown in Figures 5 and 6.

Figure 6 shows the same Vis HD frame as shown in Figure 5 with the infrared information taken using the SC655 LWIR camera registered on the upper two tiers. The two images were fused with transparency values (alpha) for the IR image set to 0.6 (60% opaque). Clearly, more details on the pallets and individual boxes are visible in Fig. 6.

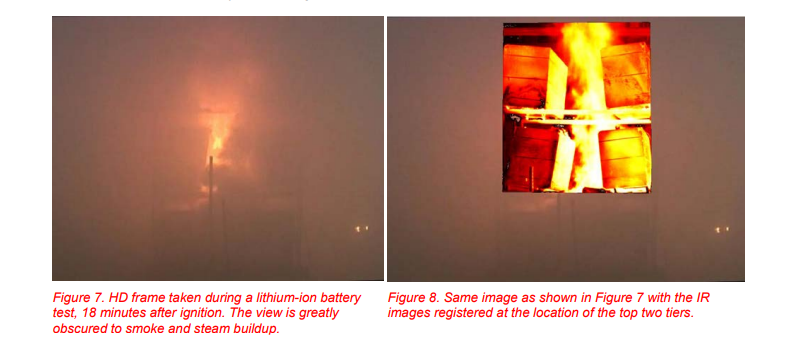

One of the key advantages of using IR imaging is the ability to see through smoke and steam and thin flames. A great example of this is shown by comparing Figures 7 and 8, which both show a test involving lithium-Ion batteries 18 minutes after ignition. Due to the fire suppression water being applied at this point during the test, the lab area filled with smoke and steam. The image from the SC655 LWIR camera is not impacted by the dense smoke and steam and information such as the fire location and disintegration of the wooden pallets is plainly seen in Figure 8.

SUMMARY

Scattering and signal attenuation from small water droplets typically obscures the fire location during large-scale rack-storage fire tests in the visible regime. However, results show that a LWIR camera (SC655) performs remarkably well, clearly showing the fire location and suppression behavior of the water through thick layers of smoke and steam. Long-wave infrared utilizes wavelengths larger than the size of steam droplets or soot particles, resulted in great signal transmittance. The surface emissivities of both virgin and charred cellulose material were determined using FTIR analysis.

REFERENCES

[1] Martinez-de Dios, J. R., Arrue, B. C., Ollero, A., Merino, L., and Gómez-Rodríguez, F. “Computer vision techniques for forest fire perception,” Image and Vision Computing, 26(4), 550-562 (2008). [2] Coen, J. L., Daily J., and Mahalingam S., “Application of infrared imagery for understanding wildfire dynamics,” Inframation Proceedings, (2010).

[3] Zhou, X., Sun, L., and Mahalingam, S., “Thermal particle image velocimetry estimation of fire plume flow,” Combustion Science and Technology, 175(7), 1293-1316, (2003).

[4] Sun H., Rong Z., Liu C., Liu J., Zhang Y., Zhang P., Wang X., and Gao W., “Spectral characteristics of infrared radiation from forest fires”. Proc. SPIE 6298, Remote Sensing and Modeling of Ecosystems for Sustainability III, 629808, September 27, (2006).

[5] Barducci, A., Marcoionni, P., and Pippi, I., “Different methods for temperature and spectral emissivity retrieval over active fires from IR hyperspectral remotely sensed data,” Proc. SPIE 5152, Infrared Spaceborne Remote Sensing XI, 296, November 12, (2003).

[6] Meléndez, J., Aranda, J., de Castro, A., and López, F. “Measurement of forest fire parameters with multi-spectral imaging in the medium infrared” Quantitative Infrared Thermography Journal, 3, 183- 200 (2006).

[7] Godding, H., “Firefighting and thermal camera use: one way doesn’t fit all,” Proceedings of Inframation, paper 2012-27, (2012).

[8] Amon, F., Bryer, N., Lock, A., Hamins, A., “Performance metric for fire fighting thermal imaging cameras – small- and full-scale experiments,” NIST Technical Note 1499, July, (2008). [9] de Vries, “In Situ calibration of a microbolometer camera for the study of large-scale fires,” Proc. SPIE 8705, Thermosense: Thermal Infrared Applications XL, 8705-1, April 30, 2013. [10] Gonzalez R.C., Woods R.E., Steven L.E., Digital Image Processing (2nd ed), Gatemark Publishing, 2009, p. 287.

[11] Ditch B.D., “Flammability characterization of Li-ion batteries in bulk storage,” Technical Report, FM Global, 2013, available at www.fmglobal.com/researchreports.

[12] de Vries and B.D. Ditch, “Multi-spectral infrared analysis of Lithium-ion battery bulk-storage fire tests,” 7th international Seminar on Fire and Explosion Hazards, Providence, RI, 5-10 May, 2013.

ACKNOWLEDGEMENTS

The authors wish to thank Mr. Jeff Chaffee and his staff for managing all large-scale fire tests. Also, the author acknowledges the thorough FTIR analysis performed by Dr. Marcos Chaos. In addition, the author is particularly grateful for their ongoing support from Dr. Yibing Xin, Dr. Christopher Wieczorek, Dr. Sergey Dorofeev, and Dr. Louis Gritzo.

ABOUT THE AUTHOR

Dr. Jaap de Vries is a Senior Research Scientist at FM Global. Dr. de Vries has over 8 years of experience in combustion-related research. He has a B.S. in Aeronautical Engineering from the College of Amsterdam, a M.S. in Aerospace Engineering from the University of Central Florida, and a Ph.D. in Mechanical Engineering from Texas A&M University. His research interests include fire suppression, combustion and flame phenomena, IR thermography, design of experiments, and gas-turbine combustion. He has authored over 35 journal and conference papers.

Dr. de Vries leads large-scale fire testing programs, and conducts fundamental fire suppression research, including the application of novel IR thermography techniques to capture the dynamics of large-scale fires, digital image processing, and heat release rate and flame emission analyses. His work has resulted

in new FM Global protection designs for the storage of distilled spirits and for flammable liquids in small metal containers. In addition, he is an instrumental member of the ongoing fire modeling efforts at FM Global; providing fundamental experimental data, which include unique measurements of surface temperatures of burning solids, fire spread rates, radiant fractions, and the interaction of water film flow with burning surfaces.