Identifying Common Issues and Misconceptions in Imaging 120-480 Volt Panels

InfraMation 2015 Application Paper Submission

Daryl Androli

Missouri River Energy Services

ABSTRACT

Imaging of electrical panels has been, and continues to be, one of the most commonly used infrared applications. Checking workmanship, improving quality/reliability, lessening risk and diagnosing potential problems are all staples of our industry. Specific issues addressed in this paper include, but are not limited to, breaker placement, overloading, wiring configuration, loose connections, neutral wire issues, and grounding. The potential damages generated by such issues will also be identified and discussed. As thermographers, we see a wide variety of lower voltage panels in a multitude of applications and misapplications. When we image these panels, are we really providing our customers with a quality product or are we taking the easy way out? This paper focuses on how to improve the overall quality of providing infrared service. Customers are willing to pay more for the technician who goes the “extra step” to provide a service that gives them a premium end product.

INTRODUCTION

The intent of this paper is to help thermographers realize that electrical problems come in all shapes and sizes. While most of our focus is on the big picture and the big problems, it is just as important to look for the devil in the details. It is always nice to find a crippling issue in a huge business, but it is just as important to find the “small” problems. Are we taking the time and putting forth the effort to look for all the issues? During my time in the field providing electrical infrared surveys, I’ve been beaten up, not by the big issues, but by the small ones. I would like to say that I’ve learned, but remember that learning is a constant process. Hopefully, this paper gives the reader some insight and provokes a thought process that helps make us all better at providing quality inspections, detecting issues and becoming a valuable part of the maintenance process.

BACKGROUND

Missouri River Energy Services (MRES) is a not-for-profit joint action agency made up of sixty-one independent municipal electric providers. In the truest form, we are public power. MRES is owned, managed and supplying electricity to the population of those cities who own and maintain their own

electric distribution systems. Any profits ultimately get plowed back into controlling costs, into maintenance, or other benefits that enhance the value of being a citizen in each community.

The MRES infrared program started humbly in 2000 when one of our largest customers asked if we would offer infrared inspection services to businesses, in addition to our normal infrared distribution maintenance service. To be honest, we thought that a few customers might use infrared services, but as an electric provider, we questioned whether it was a fad, a trend, or something that could actually pay for itself. Today, MRES employs two full-time thermographers, makes over 130 customer infrared inspections annually, offers ultrasonic and motor circuit analysis as complimentary services, and is in the process of adding staff and services.

In the past ten years, lower voltage panels, such as 120/208V and 277/480V, have been a growing area of concern for our customers. With the installation of specialized equipment, computerized processes, and even fluorescent lighting, our customers have seen a rise in the amount of problems caused by either design issues or simply poor workmanship. Focusing on lower voltage panels was not a big concern in our business 10-15 years ago. In fact, most of our imaging centered on large service disconnects, motor control centers and operations. Some hard lessons were learned early that forced us to look for the small details that pointed towards bigger problems. Overloaded panels, overheated breakers, poor connections, and hot neutral wires are all issues that plague businesses today. Even some of our competitor’s poor practices have given us a black eye in what I’ll call “flash-over thermography.” My definition of flash-over thermography is opening the access door on the panel, looking at the surface temperature of the breakers (or even worse the surrounding metal), and offering an opinion! This type of thermography doesn’t really benefit anyone. Yet there are companies today that compete with us, offering this type of service.

Thermographers need to remember some basic fundamentals, such as:

- Operating distance - Even a small distance (air gap) in a panel will affect temperature measurement

- Direct versus indirect measurements - Unless the interior or wire connection is viewed, the problem cannot be determined

- Load on the component - Is the current use consistent with normal operation?

Here are some examples:

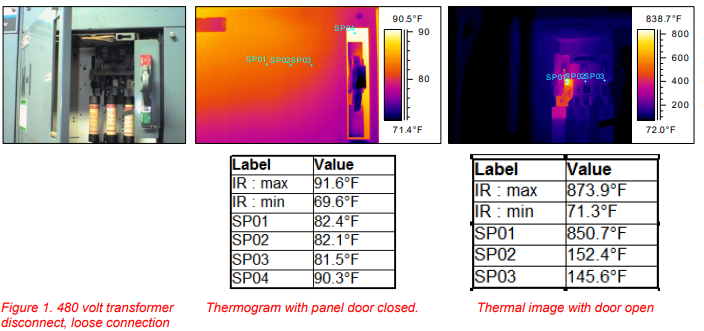

OPERATING DISTANCE

- Object: 480 volt transformer disconnect

- Problem: Riveted connection in disconnect bus-work is loose

- Potential outage: This transformer supplies power to the production floor. Losing power would completely shut down production for roughly 150 employees

Safe operating distance for the thermographer is 4 feet from the door cover. The bad connection in the disconnect is only 4 inches beyond the door cover. However, the air in the space between the disconnect and the door cover significantly diffuses the heat, obscuring the problem. Note that the heat rise on the outer door is only 10 degrees F. The heat transfer to the interior cabinet, Spot 4, is 20 degrees F. Inspection of the actual disconnect shows temperatures of over 850 degrees F.

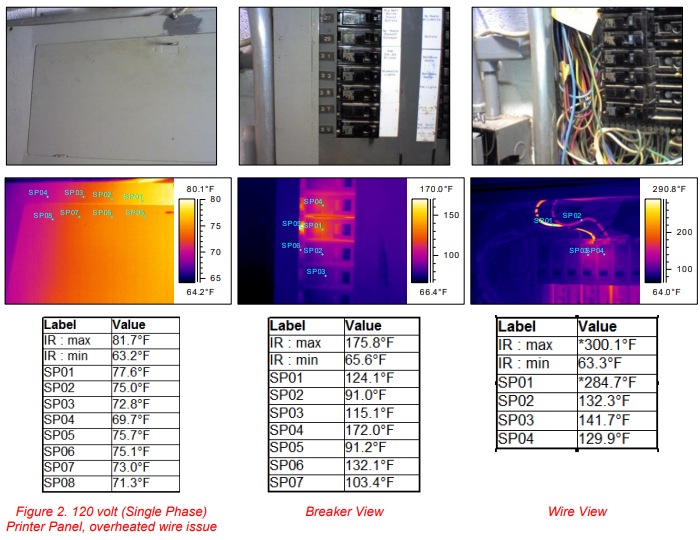

DIRECT MEASUREMENT VERSUS INDIRECT MEASUREMENT

Direct measurement of issue

- Object: 120 volt (Single Phase) Printer Panel

- Problem: Wire attached to breaker # 33 is overheated (insulation burned back 4-6 inches)

- Potential outage: This breaker supplies power to the box assembly room. Power supplied is used to print labels for boxes (before filled). The labels indicate product type and storage/warehouse placement. Failure of this printer would delay production of shipping containers, which in turn, would cause delays in product production and shipping.

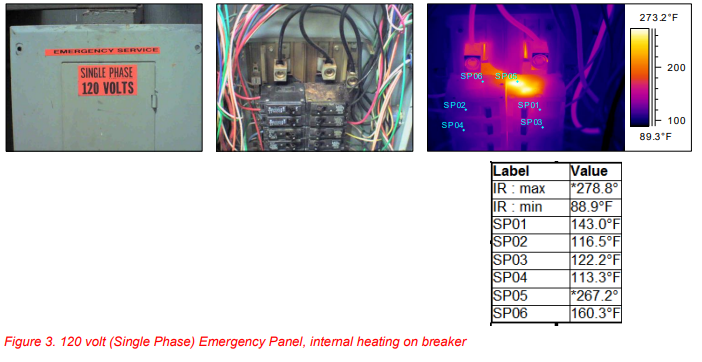

Indirect measurement of issue

- Object: 120 volt (Single Phase) Emergency Panel

- Problem: Breaker in location 2 is overheating internally

- Potential outage: This breaker supplies power to the computers that control the ammonia compressor staging for the freezer area at a major food manufacturer. If the computer fails, the system will discharge and freezer temperatures will be compromised.

Again, no visible heat signature on exterior door or on the face of the breaker! The breaker face shows temperature with normal operating range. More direct access allows shows excessive temperatures. This temperature does not indicate the true temperature of the mechanism that would allow this breaker to trip! Notice the discoloration of the breaker. When removed from service, the breaker fractured in the electrician’s hand!

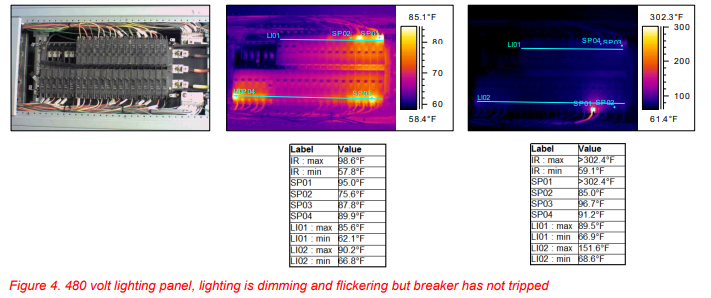

LOAD-BASED ISSUES

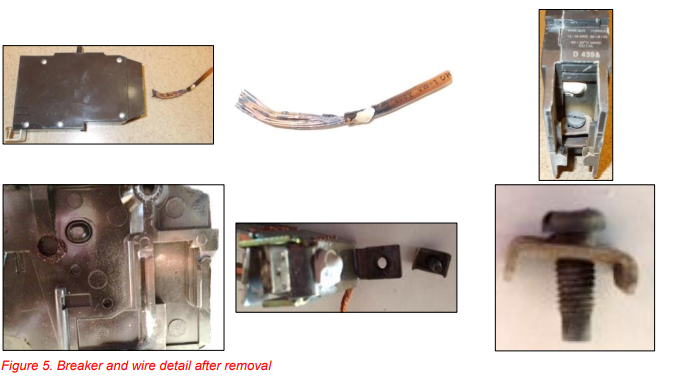

- Object: 480 volt lighting panel

- Problem: Lighting is dimming and flickering. Breaker has not tripped.

- Potential outage: This breaker supplies power to lighting on top of storage tanks in the production area. During normal daylight hours, no issue has been noticed. During the night shift, workers complained about low light levels, “flickering,” and some lights not working at all. The issue is both a safety and a potential fire hazard.

The exterior door was not imaged, but notice in the center infrared image, the highest temperature recorded was 98.6 F. When the lights were manually operated, breaker #10 temperatures rose to over 300 F! Since the lights are on an optic sensor, normal work hours/light conditions would not have indicated an issue. I was able to get the breaker and wire for this image (shown below).

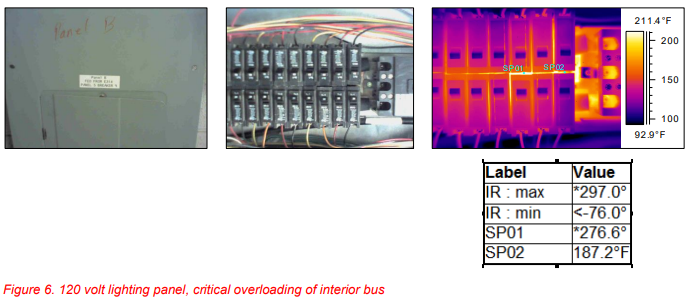

- Object: 120 volt lighting panel

- Problem: Critical overloading of interior bus.

- Potential outage: Based on temperatures, this problem could lead to complete failure of the panel involved. All machinery, lighting and load would be lost for the duration of the installation of a replacement panel or rerouting.

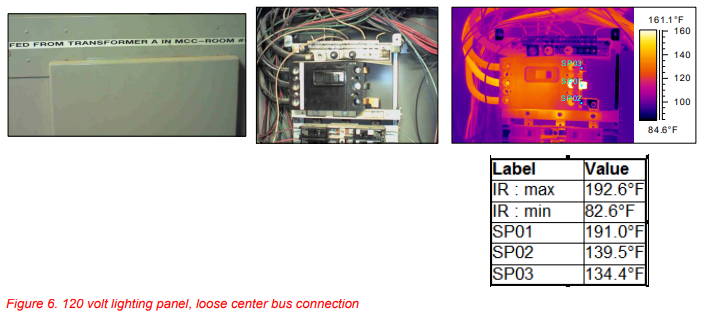

- Object: 120 volt lighting panel

- Problem: Loose center bus connection.

- Potential outage: Based on temperatures, this problem could lead to complete failure of the panel involved. All machinery, lighting and load would be lost for the duration of the installation of a replacement panel or rerouting.

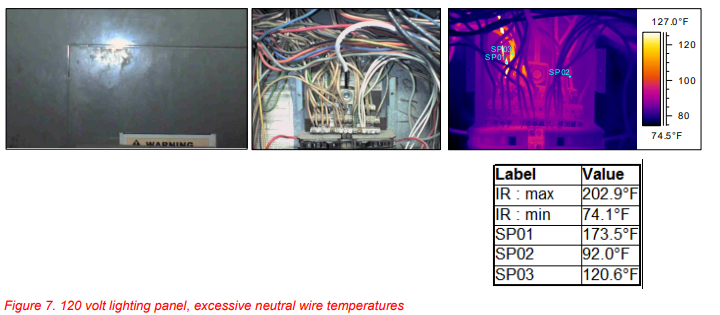

Excess heat pattern on neutral wires

- Object: 120 volt lighting panel

- Problem: Issues with excessive neutral wire temperatures

- Potential outage: This problem is multiplying with the addition of computerized equipment and tendency to use existing wiring for new installations. Lighting issues are starting to subside with the implementation of LED lighting and newer low wattage fixtures. Harmonics and conductive current remain an issue. Poor workmanship can still be the root of the problem!

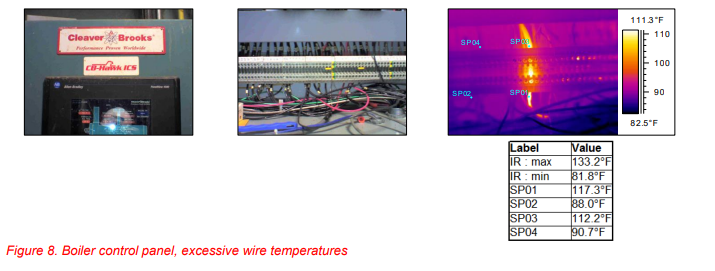

Excess heat pattern on control wires

- Object: Boiler control panel

- Problem: Issues with excessive wire temperatures

- Potential outage: This is an issue of a poor connection in a control wire block. Overheating could cause the equipment to malfunction, overheat or shut down. Simply checking for consistency in temperatures will help avoid this issue. Be aware of control voltage! Lower voltage cabinets require much tighter criticality levels. Even the slightest variance in temperature could indicate a problem.

SUMMARY

As seen with most, if not all of the images, the problems are straight forward when the thermographer puts forth more effort to diagnose the potential issue. Making assumptions on heat patterns, small temperature rises and thermal oddities will most certainly lead to failure! Without removing as many obstacles as possible, the infrared technician is setting himself/herself up for a disappointed customer.

The extra steps involved in achieving a highly successful imaging session, and a repetitive future customer, are simple. Too many times we find out that customers have little or no concept of what the thermographer is looking for, or how we make our criticality decisions. We also find out that they might have had “flash over thermography” done in the past. At MRES, our goal is to let the customer choose the type of imaging they want, over-deliver with quality results, and teach them along the way. Over 90 percent of our customer base has annual infrared imaging done. Of that group (not including our member distribution systems that also get

annual service,) over 90 percent have everything imaged to the wire connection every year! Do we find tons of problems year after year? No. Are our customers happy that we find only a few problems each year? YES! Have they worked at reducing that number and worked to prevent new issues? Most definitely! Taking all those images (25,000-30,000 annually) has saved our customers money, saved MRES embarrassment, and has grown our program immensely!

REFERENCES

Infrared Training Center, Level 1 Course Manual, Section 3, p. 35-39. Pub ITC 038 A 2002-04-30. As presented by Lyon, Bernard R. and Madding, Robert P

Acknowledgements

The author thanks Rick Bueltel (Missouri River Energy Services) for his help in collecting some of the images and providing background information used in the production of the paper and corresponding presentation. It should also be acknowledged that all the images used were from past customer surveys. These issues were presented in detail to the corresponding customers through the delivery of a problem report.

ABOUT THE AUTHOR

Daryl Androli has been actively involved in providing energy-related services to commercial and industrial customers in the upper Midwest for the past seventeen years. Mr. Androli has provided consulting services and has marketed energy-related services to the petroleum industry, the electric distribution industry, and the maintenance industry. For the past fourteen years, Mr. Androli has provided infrared maintenance services to the sixty-one member municipal utilities of Missouri River Energy Services, twenty-two associate members, and their commercial and industrial accounts, along with numerous unrelated regional facilities.