Positive IR Results In the Refining Industry

InfraMation 2004 Application Paper Submission

Robert G. Bonin, Motiva Enterprises LLC.

Inspection Dept., Port Arthur Refinery

ABSTRACT

The key to positive IR results, whether in the refining industry or in any other predictive maintenance endeavor, is to keep the camera running and to build interest in the benefits of thermography with the right people. As long as the camera is running, it can give us useful information. Finding the right people to receive the IR information is the key to the actual use of the information, and to achieving cost savings and improved reliability.

As thermographers, our job includes finding influential individuals in our organizations who can benefit from the use of IR. Using IR to locate temperature differentials is new to a lot of our operational personnel, and some of our fellow workers need to understand how the IR tool can be applied to help them. A positive and aggressive communications program continues to be the best way to get our fellow workers involved in helping us justify existing IR applications and to develop additional IR applications.

Some people are very skeptical about the reliability of IR, and others that think it is “smoke and mirrors.” Changing this attitude is a challenge—but success will go a long way in boosting your IR program. When you’re asked to take an IR scan, take the time to ask what the expectations of the IR scan are. After the scan is complete, explain what was done and the limitations of the camera, if any are found. Be very careful and present its usefulness in real terms. Do not promise helpful results for every application unless you can deliver on every promise. For example, shooting images on running units can be difficult at best, due to all the reflective energy sources in a small area. Most reflectors can be shielded and an accurate temperature produced if the area is critical and the costs are effective.

This paper describes typical uses for IR inspections and some new applications found through requests from people on the job who wanted to try IR thermography to solve an ongoing problem.

CHECKLIST FOR POSITIVE ACTION

- Take these basic steps to insure that the IR information that is captured can be reproduced and used in the future and can help identify similar areas throughout the refinery where a similar IR process will apply.

- Identify and list equipment and areas to be inspected. Alter the list as the program leads to areas that need to be included or dropped.

- Use appropriate IR procedures where and when they apply.

- Collect base-line data.

- Use base-line information you have collected and keep it updated for future trending needs.

- Establish a frequency and routing schedule for each type of equipment to be scanned. Set intervals by how critical the equipment is and the effectiveness of IR scanning. Change intervals as the faults are evaluated.

- Perform follow-up inspections and track cost savings.

INTRODUCTION

Sometimes thermal imaging information will solve problems for process personnel; at other times it helps your reliability group. In some cases we are looking for temperatures that will prove our process is working. There are also times when we can use thermography to prove something is not happening.

TANKS

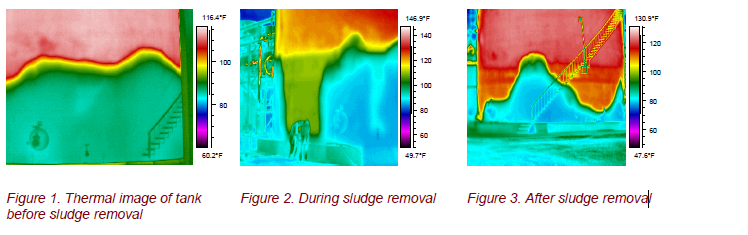

A good example of this would be measuring tank sludge levels while a vendor is cleaning a tank. Figures 1, 2, and 3 show the progress of the cleaning of a tank. Although the contractor initially reported that he had removed about 95% of the sludge, we found that the IR images could more accurately measure his progress and reveal how much sludge was actually removed. In this case, only about 60% of the sludge was removed.

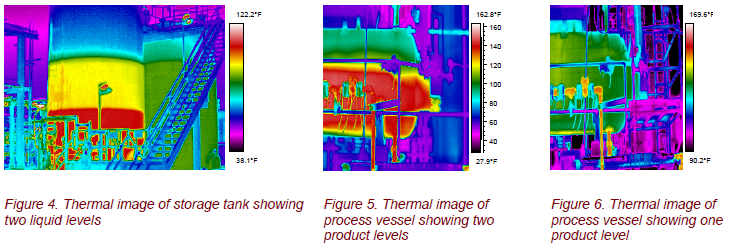

Infrared (thermal) imaging is just one of the diagnostic tools we have available to help prevent or find the cause of process problems. For example, what if you are using one product in a tank in your process and find, through thermal imaging, that there is more than one product in the tank? How might your process be affected?

The image of the storage tank in Figure 4 clearly shows three different temperatures, suggesting that more than one product—including an unknown material—is in the tank. What if the product in this tank is used to neutralize the process stream? What could happen when the unknown product is introduced to the process? A very real possibility is that the product stream will go off test! Now the real problem begins—finding out what caused the problem.

Figures 5 and 6 are images of the same vessel showing different levels of product. Which level is correct? If we are clever enough to understand what the camera is telling us, we can preempt problems and costs. We have found on the job that positive results lead people to start thinking of new ways we thermographers can help make their jobs easier and more productive.

PROCESS STREAMS

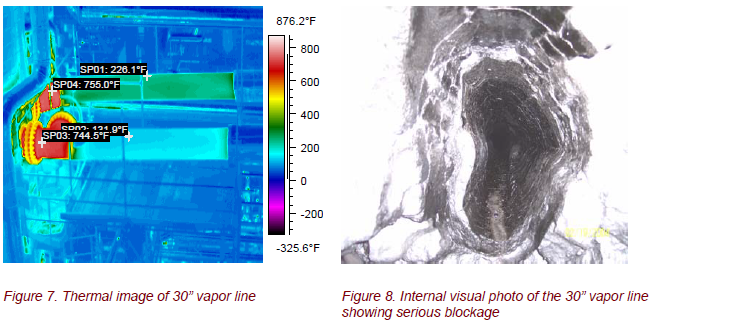

An operator requested a scan of a 30-inch vapor line that was approximately 30 feet off the ground The lines had back pressure, indicating a restriction or internal fouling. A scaffold was erected, and insulation was removed to permit access for taking IR images of a section of each of the vapor lines. The effort was well worth the cost. The IR images (Fig. 7) clearly showed that the lines were not as hot as they should have been. This gave us additional information with which to pursue the solution to the problem. On the basis of the thermal data, we expanded our work plan for the upcoming planned outage to include the cleaning of these lines, which proved to be a very good decision. After opening the lines (Fig. 8) and finding that the IR images were accurate, we proceeded with the plan to clean out the restrictions.

Having the ability to plan this work in a predictive or proactive manner, instead of having to do reactive work, allowed us to do the work without adding to the duration of the outage. This equates to full unit throughput and lower maintenance cost.

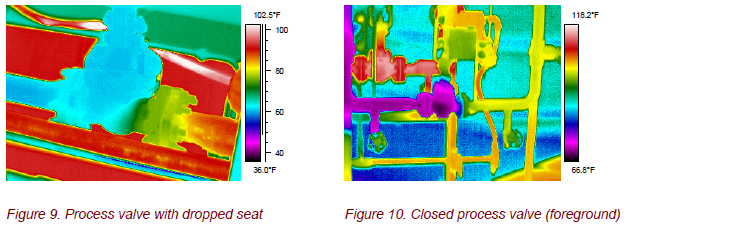

An IR image can be worth a thousand words. It can also tell you that what you see with your eyes may not be what you actually have. The thermal image in Figure 9 is of a process valve that was believed to be open. Actually, the disk had fallen off the stem and closed the valve. As a result, the valve wheel can be turned in either direction without having any effect on the temperature across the valve. Figure 10 shows a process valve believed to be leaking, but actually closed. Without the use of thermography, finding this problem would be very time-consuming and costly at best. In the petrochemical refinery there are thousands of valves that have the potential to fail. IR is a critical tool that is used to solve problems and that allows for speedy repairs to be made to the process system.

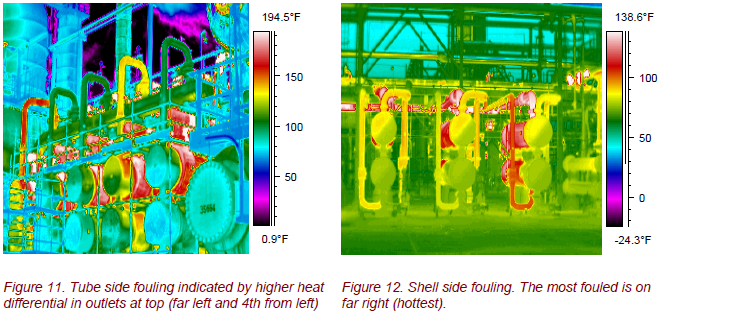

MORE PROCESS

What could be faster than using these images to find flow restrictions? Seeing these types of thermal patterns should alert the thermographer that there is a flow restriction of some kind. IR makes finding the problem easy in most cases. The information in these images would take several days to confirm using older methods. Our program welcomes operations to request IR scans to solve problems of this kind. However, keep in mind that not all temperature differentials are this clear. These exchangers are on the edge of units and have minimal added reflective energy sources to mask the image.

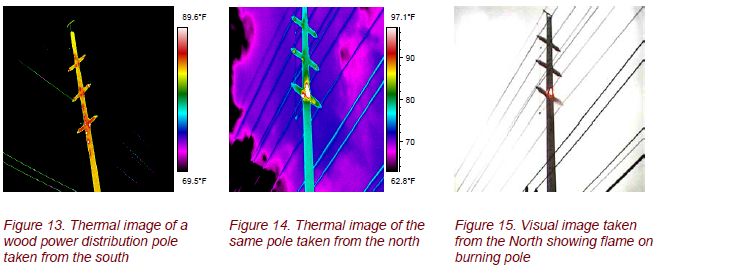

ELECTRICAL

The images below are good examples of what the IR camera can detect during a typical daily survey. Figures 13 and 14 are thermal images of a power distribution pole taken from about 200 yards away. Several warm spots were seen that alerted us to investigate further. The visual photo in Figure 15 shows that the pole is actually on fire. This fault was on a major distribution line, and the failure of the pole could have caused major electrical problems and possible unit upsets and outages. Finding this fault was indeed lucky, but without an IR program, it is a sure thing that we would have had a serious problem involving costly repairs and unit outages. Getting the information to the right person in a timely manner prevented potential unit upsets. The highline was promptly switched out of service, and the fault was corrected. The only cost was replacing the pole.

SUMMARY

Our IR program has had positive results getting off the ground due to the efforts of many people. Our management saw the potential and allowed it to expand as new applications were found. Our company is very proactive in finding innovative, safe, and cost-effective ways of solving old problems with new methods and equipment. Thermography has proven to be an extremely effective tool in the never-ending search for better predictive planning.

Our investment in infrared equipment and in training has been very cost beneficial. Our infrared inspection program is now part of the day-to-day procedure in our refinery. Meanwhile, we continue to investigate new ideas. Our experience so far strongly suggests that it may be harder to find areas where you can’t use IR than it is to develop new applications. Indeed, new IR applications keep coming in. As long as we can generate useful information with the infrared camera and communicate that information promptly to the proper personnel, our infrared inspection program will continue to be an asset.

ACKNOWLEDGEMENTS

We wish to acknowledge A. J. LeClercq of Emerson-Electric Reliability Services, John Coleman of Infrared Scanning Services, Inc, and Al Ohliger of Chevron Texaco Inc. for the directions and guidance to help make our program a positive one.