Infrared Thermal Imaging in Engineering Education

InfraMation 2015 Application Paper Submission

John S. Allen, Rintaro Hayashi, Tyler Hee-Wai

Dept. of Mechanical Engineering, University of Hawai’i Manoa, Honolulu, HI 96822

ABSTRACT

Applied scientific experiments are a fundamental part of an engineering education. A series of educational experiments, which demonstrate the value of thermography for heat transfer visualization, appropriate for undergraduate engineering students are outlined. With the increasing availability and decreasing costs of infrared cameras, it is expected their use in engineering education will increase sustainably over the next decade. These experiments are designed to directly complement the theoretical treatments covered in introductory and advanced undergraduate mechanical engineering heat transfer courses. Moreover, besides the visualization of the different modes of heat transfer, the finned sphere and melting experiments are both suitable for in-depth study and research at the undergraduate or graduate level.

INTRODUCTION

Thermography has become an increasingly important research tool for industrial, medical and military applications, but few studies have been devoted solely to education; moreover, most of these have been aimed at introductory university level physics courses [1, 2]. Notable advances in the infrared cameras in terms technology, cost and availability have occurred since an engineering education oriented study was presented [3].

The quantification and physical observation of heat transfer and thermodynamic phenomena are significant education components for mechanical, chemical and biomedical engineering students. For example, mechanical engineering students are typically required to take course in general heat transfer which is often a prerequisite to more specialized, advanced courses (conduction, convection, radiation) at the undergraduate or graduate level. The engineering courses at junior level or higher often involve in depth study of analytical and numerical solutions to the governing equations such as the heat conduction equation. Numerical solutions and simulations of governing heat transfer equations have been increasingly used in engineering curriculums with the use of commercial software packages. However, physical experiments and associated training with laboratory equipment remain an irreplaceable part of engineering education. .

Thermal imaging cameras display images of infrared radiation and offer a non-contact method of measuring surface temperature changes from a distance. The laboratory experiments were designed provide insight into thermal design considerations as the different modes of heat transfer. The experiments were conducted using the FLIR SC655 Camera (25° Lens) utilizing a 640x480 pixel detector with sensitivity of <50mK. The camera is capable of 14-bit digital data at 50 frames per second which was important in capturing details of convective heat transfer processes. The cameras facilitate the visualization of the patterns of natural convection and these can be viewed simultaneously with those obtained with an optical video.

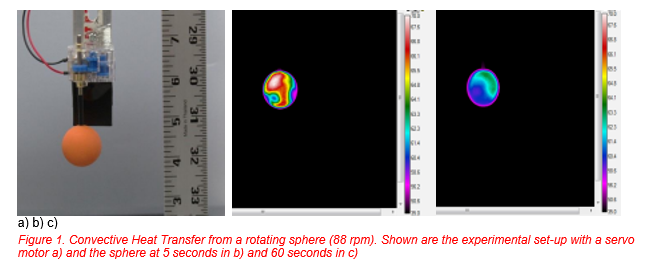

CONVECTIVE HEAT TRANSFER OF A ROTATING SPHERE

Many heat transfer textbooks and course experiments examine the convection from a stationary sphere [4]. Correlation relationships with respect a function of Nusselt number for range of Grashof numbers have been reported. However, a variety of applications require an understanding of the convective heat transfer from a rotating body to the surrounding fluid. Engineering examples include rotors, shafts, drills and flywheels; however, cost and safety make these impractical for engineering educational labs. Likewise, the idealized geometry of an isolated sphere is amendable to comparison with empirical correlation formulations. Quantification of the temporal and spatial cooling of a rotating heated small rubber sphere is difficult with traditional thermal couple measurements due to the complex convection patterns. However, thermography provides novel insights into this cooling process as shown in Figure 1.

The rotating sphere case can be compared to more comprehensively studied stationary case. Figure shows results for a rubber sphere for which the Biot number is greater than 0.1 and this experiment has also be applied to metal spheres with Biot numbers less than 0.1.

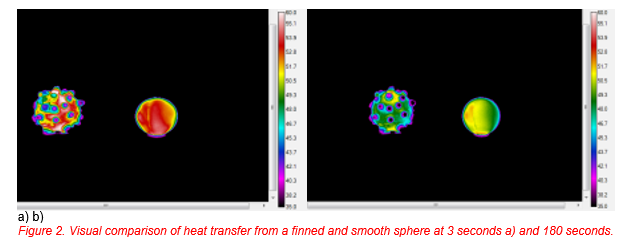

NATURAL CONVECTION – FINNED SPHERE

Extended surfaces are widely used to increase the rate of heating or cooling of solid objects. The heat transfer from a single model fin has been examined in research and undergraduate labs but the cooling for finned objects has received less attention. Analytical solutions for a single fin are well-known which allows for direct comparison with thermocouple measurements. The heat transfer from a finned sphere

is topic of current interest with direct applications to thermal design of lighting and other electronic devices [5]. Figure 2 shows the natural convection from a smooth rubber sphere and finned (spiky sphere) of comparable size with fins approximately 2 mm in length. A heat gun was used to heat the spheres to 58 C.

The convective heat transfer at the fins is readily apparent as is the more rapid cooling of the entire solid body surface. Extensions to this laboratory include the influence of forced convection and role of different sphere materials.

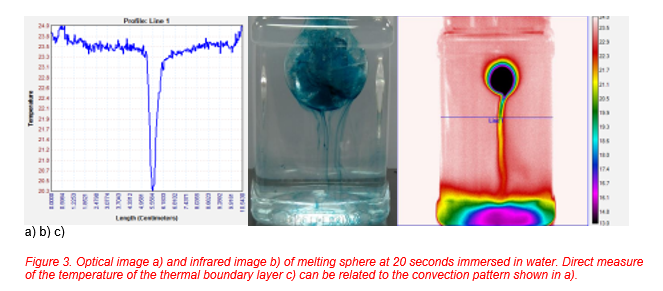

MELTING OF AN ICE SPHERE

The visualization of heat transfer by boundary layer natural convection is of interest for ice undergoing a phase transition through melting. Shown in Figure 3 is the optical and infrared visualization of the melting of an ice sphere. The infrared image allows for direct visualization and measurement of the temperature in the boundary layer of an ice sphere (66.6 mm in diameter). A thin plastic film container with limited Infrared absorption was used for immersing the sphere in water.

SUMMARY

-

Infrared thermal imaging has a strong potential for extended incorporated in undergraduate and graduate engineering education thermos-fluids curriculum. It facilitates the visualization of the different modes of heat transfer which fosters physical insight into design and experimentation.

REFERENCES

- Jones, D.; “A way to see ‘invisible’ infrared radiation”, pp. 18-19; School Science Review, 92(339), 2010

- Mollmann, K.P. and Vollmer M.; “Infrared thermal imaging as a tool in university physics education,” pp. S34-S50, European Journal of Physics, 28 (S37), 2007.

- Cabello, R., Navarro-esbriâ, J, Llopis R, Torrella E.; “Infrared thermography as a useful tool to improve learning in heat transfer related subjects”, pp. 373-380, International Journal of Engineering Education, 22(2), 2006.

- Kreith, F., Manglik R.M., Bohn M.S.; Principles of Heat Transfer, 7th Edition, Cengage, 2011.

- Singh, B.; Dash S.K.; “Natural convection heat transfer from a finned sphere”, p. 305-324, International Journal of Heat and Mass Transfer, 81, 2015.

ACKNOWLEDGEMENTS

The authors thank the Dept. of Mechanical Engineering at the University and the UH College of Engineering for support. Also the authors acknowledge additional support from the DHS.

ABOUT THE AUTHORS

John S. Allen is an Associate Professor of Mechanical Engineering at the University of Hawaii-Manoa. His research interests include acoustics and fluid mechanics. He has an AB degree in Physics from Princeton University and a Ph.D. in Mechanical Engineering from the University of Washington.

Rintaro Hayashi received a BSME degree from University of Hawaii and is pursuing his MSME degree at the University of Hawaii with graduation expected in Spring 2015.

Tyler Hee-Wai received an undergraduate degree in Bioengineering from USC and an MSME degree from the University of Hawaii. He is currently employed at Pearl Harbor Shipyards.