Identifying Issues On Installed Photovoltaic Systems Using Thermal Imagery

InfraMation 2016 Application Paper Submission

Fredrick Brooks

Pacific Panel Cleaners LLC

ABSTRACT

Photovoltaic systems are a great renewable energy resource and they need to be inspected and maintained regularly. Inspection of the photovoltaic modules with a thermal imager is critical to identify any problems. Thermal inspection is necessary on the balance of system including the inverter, combiner boxes and system disconnects. If there are issues in the modules or on the balance of system this can cause a loss of energy which is a directly parallel to a loss in money. If there is a problem that goes undetected and is left in the system, it can lead to a fire which is very dangerous and is also very costly. The use of the thermal imagery with the other data collected on a site is an invaluable tool to determining the health of the installed photovoltaic system.

We will answer the following questions:

- What are we able to see?

- How can we tell if this is a real issue or not?

- What are some of the causes for the issues we can find?

- What can be done with some of the issues when found?

- What are the conditions for conducting a proper thermal scan with true results?

INTRODUCTION

With a photovoltaic system as with any piece of equipment that someone owns there is a level of maintenance that needs to be done to keep that system up and operating and in the best condition. During the years of owning a photovoltaic O&M company the thermal imager has become, by far, one of the most critical pieces of equipment in our tool box.

As with any thermal imaging tool you need to understand what you are looking at and should have a working knowledge of the equipment to understand the measurements. The thermal scanning that is conducted does not just look at the installed photovoltaic panels but also the other electrical equipment associated with the photovoltaic panels. There are certain elements that need to be taken into consideration when conducting the thermal scan on the installed photovoltaic (PV) system. These basic PV definitions and terms need to be understood for this document.

DEFINITIONS

Photovoltaic (PV) – the ability to produce electricity from the suns radiant energy. This is also known as PV and for the rest of the document we will refer to it as PV

Panel- this is the term used for each individual solar panel

Cell- this is the block inside of the panels, panels have up to 96 cells per panel average numbers are 60 and 72

Diodes- There are 2 types of Diodes one is a bypass diode the other is a blocking diode. The bypass diode allows current to pass a damaged cell, a blocking diode stops current from flowing backward Junction box- place on the back of a PV panel where all the cells are connected to and give the panel its full rating. This is where the connectors go to another panel to create a string.

String- a series of panels in a row all connected

Combiner box- Place where the strings all meet to run in parallel this is where all the strings current is added together and the voltage stays the same and where a main wire goes to the systems inverter Inverter- The unit that transforms (inverts) the PV panels DC into AC for use with our common electrical systems

Irradiance- The measurement of the suns energy striking the earth’s surface and the PV panels surface this is measured in watts per meter squared shown as w/m2, this is very important as this has a direct effect on the PV panels current output.

WHAT ARE WE ABLE TO SEE?

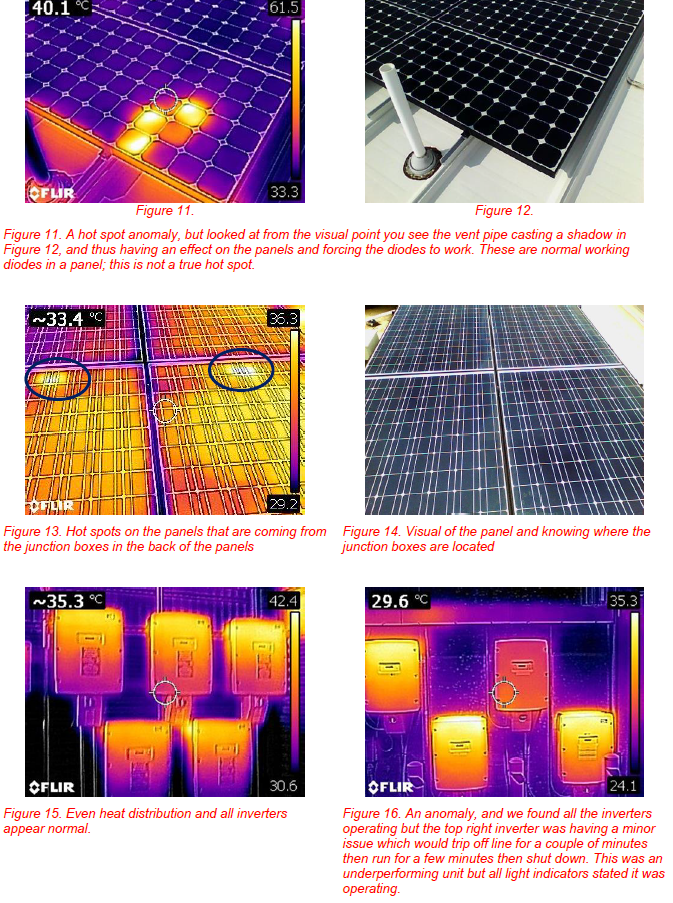

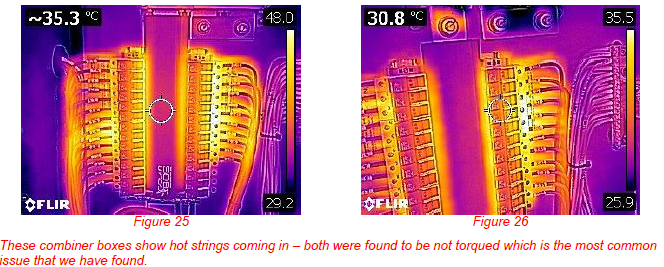

When conducting a thermal scan of the panels you are able to identify hot spots on cells of a panel, notice if a diode has failed, or is working depending on the condition, or if there is major dirt or staining on a panel. You can see the junction boxes on the panels and know they are working as they have a higher heat signature. Inside of the combiner boxes you are able to see if there is a hot string entering the combiner box or if there is a dead string. This can indicate either the line is not torqued properly or if there is a production issue. The inside of system disconnects this is the main system knife edge disconnects for electrical equipment where you can see if a line is overheating. On the inverter you are able to see if you have proper ventilation occurring, you can also tell if an inverter is not producing what it should be in comparison with the other inverters in the area.

These are some of the basic items we are able to find easily with the thermal camera helping to determine the health of a PV system.

HOW CAN WE TELL IF THIS IS A REAL ISSUE OR NOT?

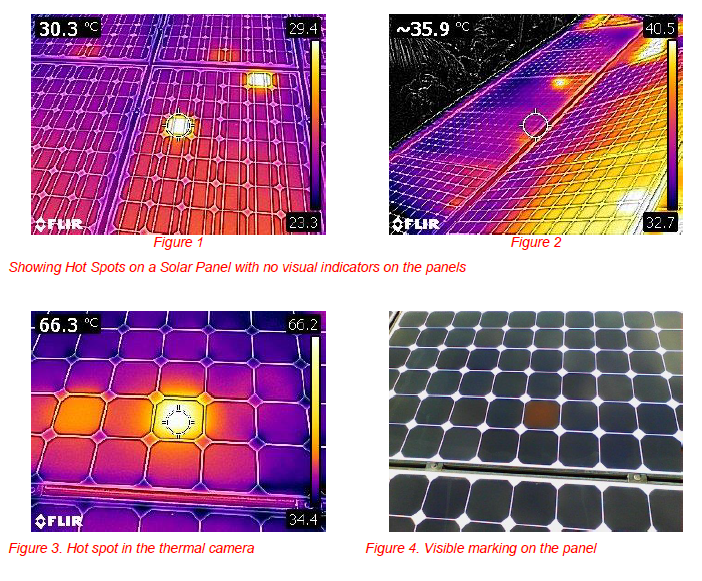

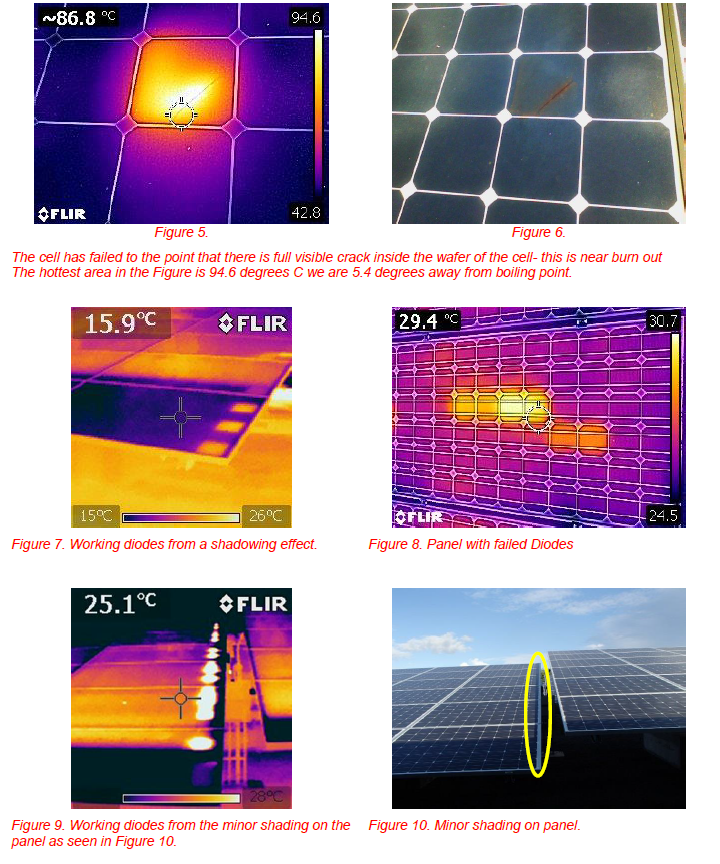

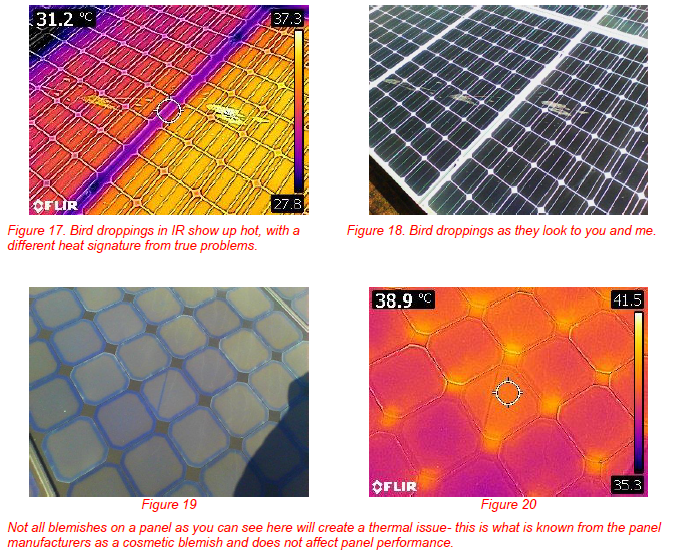

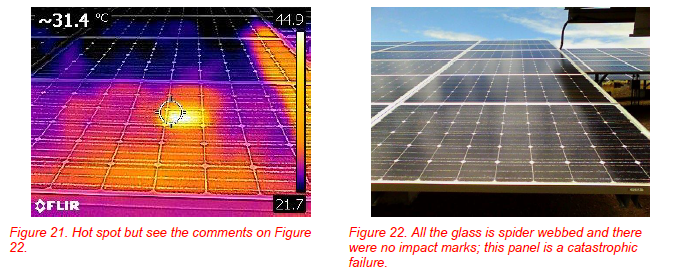

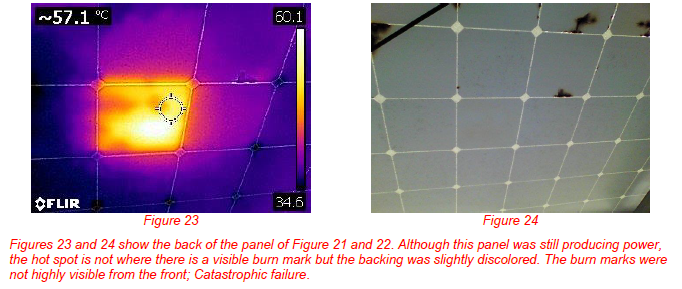

When we are conducting our thermal scans of the system the beginning part of the scan is a preliminary analysis to see if there are any anomalies. The reason being there are some items that are truly not issues that come up as thermal scan hot spots. When determining the authenticity of a hot spot a more in depth analysis needs to be conducted. One of the quickest hot spots that comes up that is not a true issue are from nature (bird droppings, trees sap, dirt, etc.)

With all thermal imagery work you are aware of your surroundings and shadowing so you always want to take a couple of images from different angles to see if it is truly an anomaly. When thermal scanning any of the equipment you need to note your irradiance at the time of the scan. On a solar panel you will need to shoot the panel hot cell and surrounding cell to find the differential temperature (Δt) as this is going to let you know if it is a serious issue or not. Here are some of the basic guidelines from our experiences:

Solar Panels

- Under a 5°C Δt not a major issue

- 5-10˚C Δt note it and see if there is anything that might be causing this issue- ∙ Greater than a 10˚C Δt is an indication of a problem and further actions need to be taken

Inside of a combiner box and a service disconnect

- Under a 2˚ C Δt is not a real issue

- Above 2˚ C Δt needs to be addressed

Inverters are a bit different as the thermal scans are comparative with side by side inverters to ensure the proper cooling is taking place on the equipment or if one unit is not working. You are doing the thermal scan on these units as if looking for a leak and making sure the heat is being dissipated properly.

WHAT ARE SOME OF THE CAUSES OF THE ISSUES WE HAVE FOUND?

Some of the causes of hot spot issues:

PV panels

- External damage (golf balls, baseballs, tree limbs etc.)

- Shading issues

- Diode failure

- Catastrophic failure the panels sometimes just shatter and the jury is out to what caused these issues.

With a PV panel with a catastrophic failure it is really important to get as much information as possible on the site location, site conditions, location in a string and all the electrical information you can about the panel.

Combiner boxes

- Torque specification has not properly met

- The string is a higher performing string and can cause heat

- The string has failed and is no longer producing (this is when we would see a cold line) - this can be caused by a string being disconnected. Blown fuse in the combiner box.

Inverters

- Inverter ventilation covers not properly sealed

- Unit is not operating

- Poor ventilation (externally or internally such as the intake screens or blocked or a failed fan) ∙ Unit has a problem with the PV system not performing as designed and is under producing.

WHAT CAN BE DONE WITH SOME OF THE ISSUES WHEN FOUND?

Always perform a full visual inspection and document what is seen. Then continue on with the further testing.

PV panels

- Map out the location and identify the string number it is associated with (do this with all hot spots found even if they are not at the major issue phase)

- Identify what might have caused the hot spot

These next steps are if the panel is a major issue

1. Take a minimum of 3 thermal images from various angles and be sure to have irradiance readings

2. If there is a replacement panel change that panel out of the system

3. If no replacement is available start the warranty claim process with the panel manufacturer 6. Always inform the customer of the situation and if there are no spare panels available let them know that it is recommended that the string be shut down until a replacement panel is available 7. If there are obvious burn marks it is recommended to immediately shut down the system.

Combiner box

1. Note the string and what system it is on

2. Visibly inspect the area to ensure the wires are not damaged or there are no obvious issues in the box

3. Test the fuse and ensure the fuse has not blown

4. Perform system checks on the string, this would be the voltage and current checks and ensure to have the irradiance at the time of the check. This will be a good comparative analysis with like strings under the same condition going to the combiner box. Some strings will have a greater current and that can be the reason for the hotter temperature.

If none of these are the items continue to the next steps

5. Perform a torque check on all the strings and ensure they meet the torque specifications on the box.

6. Upon completing these steps turn the system back on, let the system run for at least 15 minutes – perform a new the thermal scan to see if this has cleared the anomaly if it was not torqued properly

If this has not corrected the anomaly further investigation and testing will be required. This work falls under PV testing and maintenance.

Inverters

1. Check to ensure the unit is running

2. See if there are any physical items blocking it

3. Verify the strings and system energy going to that inverter

With all the items good documentation is the key element and if it is a major issue, be sure and contact the manufacturer with:

1. State that you are a certified thermographer and found an anomaly on a PV system and found an issue

2. Site name

3. Site address

4. Contact information

5. Serial number

7. What exactly was found (if there is a large Δt, burn mark, no visible signs, or any significant items)

WHAT ARE THE CONDITIONS FOR CONDUCTING A PROPER THERMAL SCAN WITH TRUE RESULTS?

The ideal conditions for conducting a PV system thermal scan are:

1. The system needs to be operating with no fault conditions

2. Irradiance is greater than 600 w/m2

3. Weather condition is stable

4. Full knowledge of the installed PV system

5. Have the system layout and mapping preset to do the thermal inspection.

Panels are tested under certain test conditions 25°C, at 1.5 Atmosphere condition (which you will not have any control of) and at 1000 w/m2. Since the atmosphere condition is going to be a constant at your location and you are going to be doing a comparative analysis its critical to get the temperature and the irradiance at the time of the reading since you can calculate a proper answer.

You are able to find thermal anomalies in low light conditions, we have found anomalies on systems with irradiance as low as 100 w/m2 coming to the panels, but with higher irradiance we have found better results.

SUMMARY

Photovoltaic systems have a lot of areas that can be thermally scanned to find out the proper system health. There are items to check to ensure there are no true issues in the system. A proper system commissioning done using the thermal imager and documented at the start of the systems life as well as an annual system inspection with the use of a thermal camera that will ensure the solar investment is at its peak performance. Whenever there is a loss to heat that is a loss of energy which is a loss of money. Scan the photovoltaic systems at least once a year and keep good documentation from year to year, equipment fails, thermal imaging can find those failures.

ACKNOWLEDGEMENTS

The author wishes to thank Gary Orlove, the Infrared Training Center at FLIR Systems and to Randy Corey from Sustainable Power Group who many years ago encouraged me to become certified thermographer so I can truly do proper photovoltaic O&M.

ABOUT THE AUTHOR

Fred has owned and operated a photovoltaic O&M company in Hawaii for over 7 years and has been involved in the photovoltaic industry for 10 years. Served in the United States Navy in the engineering department for 8 and half years prior to getting a BS in Environmental Science from Hawaii Pacific University and pursuing his career in the photovoltaic industry. Has been certified thermographer for over 3 years .Continues doing other work in the energy field and is a Certified Energy Manager and a Certified Energy Auditor, all areas that the use of thermal imagery plays an integral role.