Checking for flaws in spray foam insulation using infrared and blower door

InfraMation 2015 Application Paper Submission

Randy Kiez

ATLAS Infrared Inc. (exp Services Inc.)

ABSTRACT

Spray applied polyurethane foam (SPF) is recognized in the construction community as having superior thermal insulation properties, high resistance to air flow through it, and (depending on the type) good vapour diffusion control, as well as other desirable characteristics. SPF is often specified for use in high performance buildings, retrofits, and in hard to reach locations where 'typical' products may be difficult to install. However gaps in the cured product may permit water vapour, carried by air flow, to be deposited in the building 'envelope' where it can condense and cause problems. This can be a critical flaw especially when it is intended to be part of the air barrier system.

INTRODUCTION

Due to is monolithic nature, SPF is often perceived as having infallible air control however this is not necessarily the case. Errors in its application and movement of the substrate against which it is applied can compromise its performance.

Using a blower door(s) to manipulate air pressure within building and an infrared camera to capture the subsequent air movement can be very effective to pinpoint air leakage areas. The technique is useful for diagnosing problems with existing SPF applications as well as for quality control of newly applied SPF.

By isolating the problem targeted repairs can be made rather than undisciplined and overly disruptive tear-outs.

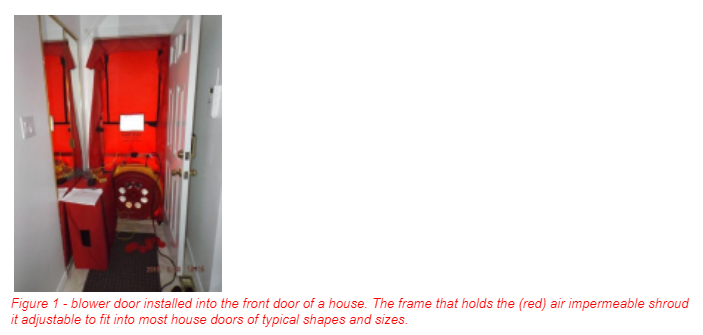

BLOWER DOOR

Blower doors are calibrated fans that are fitted into a building opening (ie. door) and are used to create a positive or negative pressure (depending on the problem at hand) between the outdoors and the inside of the building. In single family residential, the focus of this paper, a single fan is usually all that is needed. A blower door setup is also equipped with a manometer to take air pressure readings.

AIR LEAKAGE PATTERNS

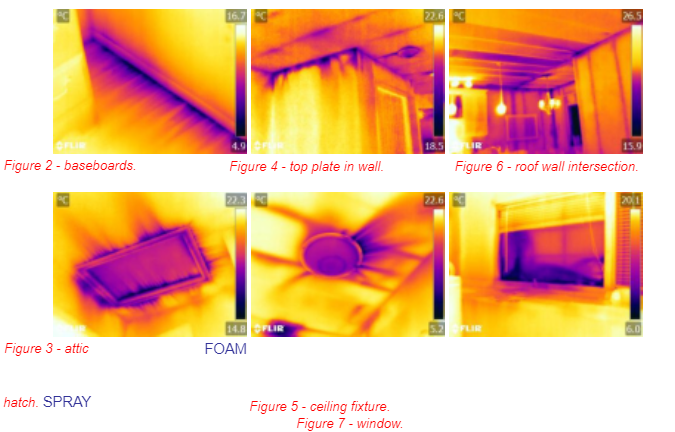

Air leakage visible in an infrared camera appears as wispy lines as it passes over a solid surface.

The advantages of using a blower door to induce air movement include:

- Controllable air pressure - the thermographer is not reliant on turning on house fans or waiting for wind to move air through gaps in the building envelope.

- There can be a much narrower temperature difference ('Delta T') between the exterior and interior environments down to even just a few degrees and the passing air will still create a recognizable thermal pattern.

The following images are examples of what induced air leakage looks like.

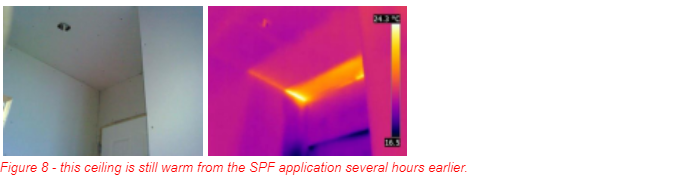

Spray polyurethane foam is a plastic made by the precise mixing two chemicals each of which are shipped in liquid form in separate barrels to the job site. The spray foam apparatus consists of hoses long enough to get into the building at the end of which is a mixing nozzle. As the separate chemicals exit the nozzle they mix and quickly react in an exothermic reaction to create a foam that will adhere aggressively to suitable substrates.

The various SPF foam types are differentiated by their internal cell structures and weights and each type has its own advantages depending on intended usage.

'Closed cell foam' is rigid in nature and has air barrier and vapour retarding properties. Its internal cells remain closed trapping the blowing agent gas and yielding a high R-value insulation in comparison to other insulations. The high density variety is often specified for roofing applications while the medium density is used in wall cavity fills, attics and areas such as basements that may be subject to liquid water.

'Open cell foam' is more flexible than the closed cell variety and its cells are filled with air. It is referred to as low density foam. It is an air barrier at certain thickness but is vapour open and may require a vapour retarder depending on climate zone. It is often used in wall cavities and attics.

APPLICATION CHALLENGES

SPF must be applied within a range of specified ambient environmental parameters onto an appropriate prepared surface in accordance with the manufacturer's instructions.

While applicators generally receive product training and certification, SPF is still a field applied product subject to flaws in application. There are two general types of flaws in SPF application:

1. Applicator negligence.

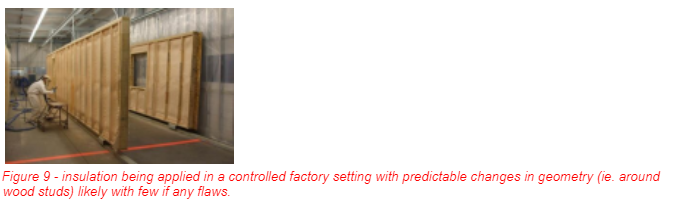

2. Flaws that could be attributable to the rapid expansion of the product. In general, these occur around changes in geometry such as at the corners of framing members.

It is relatively easy to apply SPF to consistent substrates that do not have changes in geometry and these areas seldom have problems.

BLOWER DOOR SAFETY

This paper is not intended to give instruction on the correct and safe use of blower doors however one precaution should duly be stressed.

If creating negative pressure within the building combustion gases from furnaces, boilers, water heaters, etc, and ashes and burning embers from wood burning appliances can be drawn into the building with dire consequences. Those who undertake using a blower door should get proper and adequate training.

TESTING FOR AIR LEAKAGE IN THE SPRAY FOAM APPLICATION

The following is a suggested method for testing:

1. Walk the building closing all the windows, doors and other openings that would require the blower door to run at a higher than necessary speed.

2. Temporarily shut down appliances as noted in 'Blower Door Safety' above. Make sure to turn them back on (especially in freezing weather).

3. Set up the blower door.

4. Do a thermal scan without the blower door running to baseline the known or suspected problem area(s).

5. Start the blower door. Note that it is prudent to record the blower door readings using the manometer and file the results. If there is a subsequent visit the client may ask if there was an improvement in air leakage control and without initial readings this would not be known.

6. With a narrow Delta T let the blower door run for a while; with a large Delta T thermal scanning can begin within a few minutes. Be patient - with air leakage the results develop like a Polaroid picture.

7. Record all interesting images and even those that are not necessarily interesting but show something.

8. Do the report and send out as soon as possible.

9. If at all possible, be there for the demolition of suspected faulty areas or ask the client for pictures as validation of the thermal findings.

TESTING FOR AIR LEAKAGE DURING THE SPRAY FOAM APPLICATION

It may be tempting to doing the actual testing simultaneously with the spray foam application, and while the author admittedly does not have experience in this department, it is not a recommenced practice.

The foam spraying process releases tiny particles of foam which will adhere to anything and everything that it touches including the tester's equipment. Further, applicators wear respirators for a reason and breathing the gases is not advisable especially in front of a blower door which is concentrating the air flow in one location.

IMAGES AND EXPLANATIONS OF VARIOUS SPRAY FOAM DEFECTS

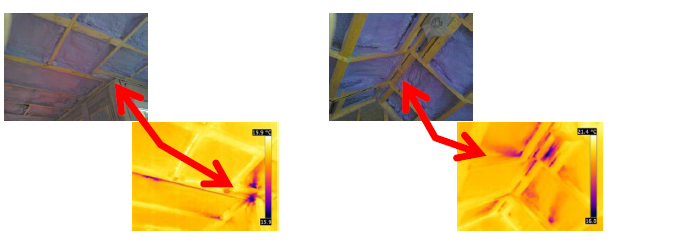

1. New House - 2x4 Wood Frame Construction

Background: To save internal real estate the builder used 2x4 framing (rather than 2x6) and to make the home comparatively energy efficient used 2 pound spray foam in the walls and vaulted ceiling. There was substantial air leakage in the ceiling even to the extent of moving the Code required polyethylene vapour retarder. The builder wanted to proof the quality of the SPF application and was aware of the consequences of concealed air leakage at the upper reaches of a tall ceiling in a two storey house (ie. stack effect and condensation)

Solution: Builder had the spray foam company touch up the areas that had air leakage which was easy to do as the ceiling boards were not installed.

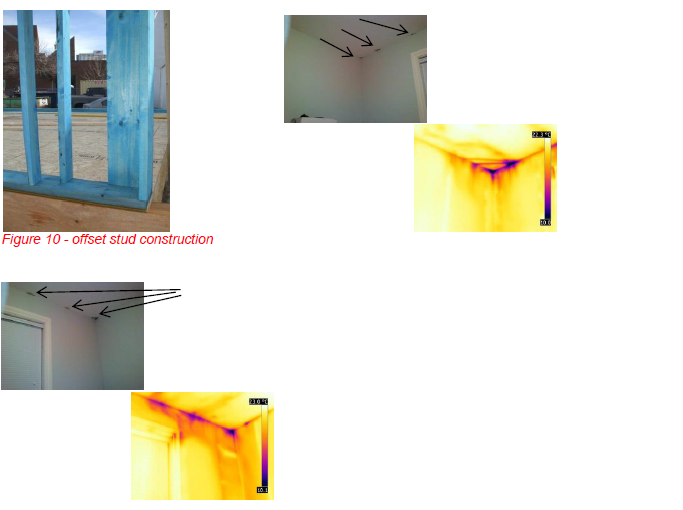

Newer House - Staggered Stud Construction

Background: Air leakage within the wall cavity was causing cools spots creating conditions for mould to form. The SPF applicator was reportedly inexperienced and seems to have missed covering the top plates. Staggered stud construction is a method to increase the thickness of a wall so that it can hold more insulation (also called offset stud). Mould at the junction of the wall and ceiling is indicated at the arrows and wispy lines of air leakage within the wall cavity could be seen at every mould spot.

Solution: The home owner was upset with the applicator but realized there was not much he could do. In reality, the mould occurred during the initial drying period of the home when interior humidity was high. This condition may be controllable by having a less humid indoor environment.

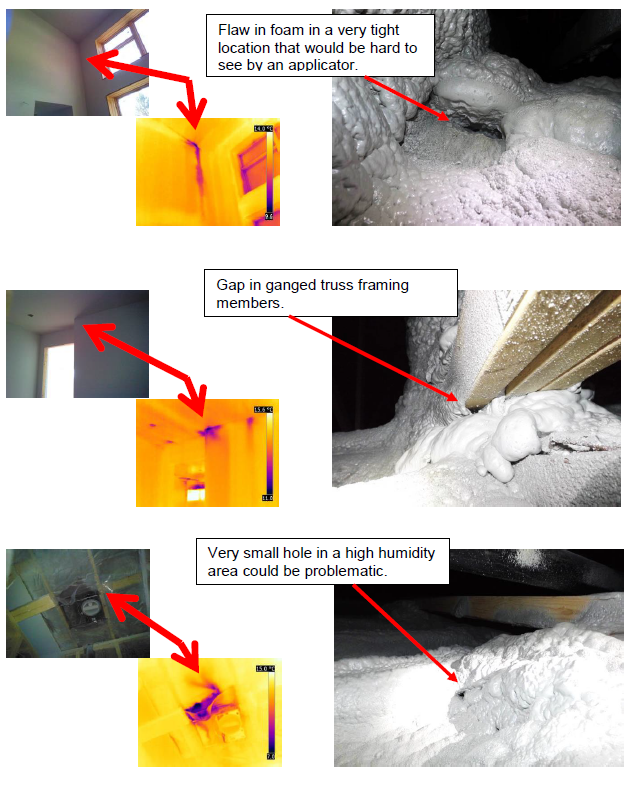

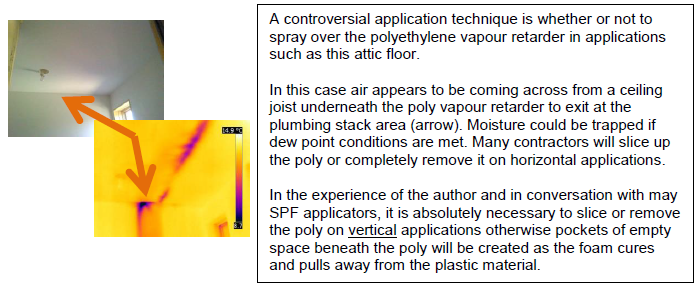

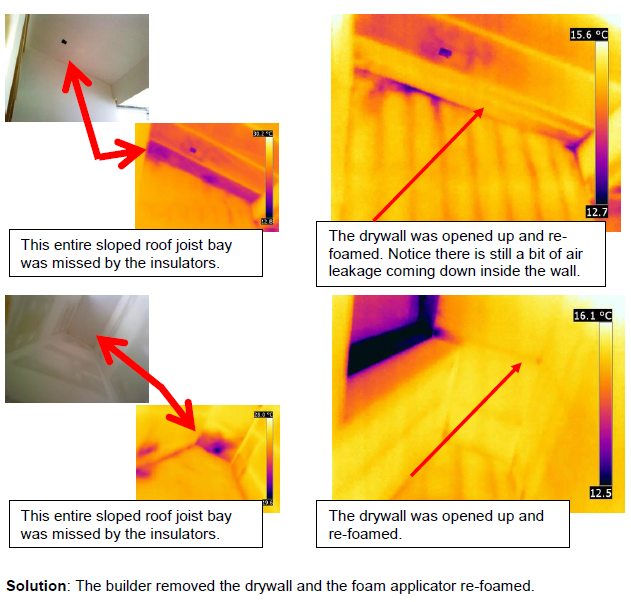

Existing House - $1.5 Mil. Dollar Renovation

Background: Air leakage in the ceiling plane. The contractor was very picky as was their client who wanted to create an energy efficient home.

New House - $4.5 Mil. Dollar

Background: Shoddy installation by the foam contractor.

CONCLUSION

1. Spray foam applications can be tested for air tightness integrity using a blower door and infrared camera combination. In fact, these tools are inseparable for building diagnostics of this nature.

2. Changes in geometry between building materials is often a place where air leakage occurs through gaps in the SPF.

3. Spray foam must have a good substrate for proper adhesion.

4. Spray foam must be applied at the right environmental conditions

REFERENCES

Guidance on Best Practices for the Installation of Spray Polyurethane Foam, Spray Foam Coalition of the American Chemistry Council’s Center for the Polyurethanes Industry, 2012

www.polyurethane.americanchemistry.com

ABOUT THE AUTHOR

Randy is a building science technician with Exp Services Inc., and also operates his own company, ATLAS Infrared, through which the houses in this presentation were investigated. Randy has done in excess of two thousand blower doors and recently received Level III thermography certification. He has been a thermographer for over six years and a residential energy advisor for thirteen years.