Aerial Thermal and Visual Inspection of Electric Lines with an Unmanned Aerial System

InfraMation 2018 Application Paper Submission

Author: Brandon Rench, CP, LII,TIR

ABSTRACT

Our client has 770 miles of electric Distribution and Transmission lines which provide electric service to roughly 28,000 customers. With an ever-increasing population in the county, the local municipal utility realized a need to expand its services for residential and commercial communities alike. Thus, the electric municipality set out to define the items needed to keep up with masses, and the goals that the project achieved were three-fold: Identified and reported thermal and visual anomalies, demonstrated how technological advancement serves as a valuable resource and provided solutions to add future value to electric improvements and maintenance for the utility.

A UAS inspection showed how a progressive electrical utility and an innovative surveying company could collaborate to create an ‘out of the box’ solution to improve a traditional process and demonstrate that the synergy of UAS and thermal technology could provide future value to electric operations and maintenance.

INTRODUCTION

To meet the electric service needs of the increased population in their Local County and city area, a local municipal utility teamed up with Surveying and Mapping, LLC (SAM) to pursue a new approach for inspecting their aging electrical system. Headquartered locally, SAM has an extensive background in aerial geospatial services and had recently partnered with the utility on smaller thermal UAS pilot projects. After a thorough analysis of local aging assets, the utility invested in an aerial inspection project with SAM of approximately five (5) miles of three-phase electric distribution lines in a downtown, heavily visited tourist city. Without this inspection project, the city could have encountered outages which would have cost the customer loss of revenues. Instead, it allowed the utility to repair potential outages before they occurred and save them and the community money by avoiding after-hour outages while providing information to improve the safety of employees that are responding.

The project used new technology and techniques to increase the efficiency and safety of traditional inspection methods. SAM’s UAS systems were able to successfully identify and report thermal anomalies

on the electrical equipment, identify vegetation encroachment, and visually locate assets in need of repair. Traditional helicopter, bucket truck, or ground based inspections would have had increased project durations, limited the perspective of the inspection, impeded local traffic, and/or caused disturbances to the busy downtown community and tourist locations, whereas, the field operations for the UAS inspection were completed in less than 3 days without hindering traffic or normal community operations. The utility and SAM demonstrated the ability to pilot a project that added significant value to the electric industry. The methodology allowed the utility to continue to improve operations within the communities it serves while saving valuable resources.

PROVIDING TECHNOLOGICAL SOLUTIONS

The project used new technology to increase the efficiency and safety of traditional inspection methods. An appropriate UAS was selected that would be able to hold the payload with an increased flight duration. SAM installed and equipped the UAS with a coupled thermal and visible camera payload. The integration of these cameras was developed so that each photo was synchronized, and the utility could compare thermal anomalies with a visible photo providing a clear picture of the equipment in need of repair. The addition of the synchronized 30X optical zoom camera proved to be an absolute necessity due to the detail that was visible when reviewing thermal anomalies, as well as non-thermal equipment issues. The thermal camera was also capable of capturing fully radiometric imagery, so temperature analysis could be performed.

IDENTIFYING & REPORTING ANOMALIES

Due to stringent FAA guidelines regarding commercial UAS usage, a three-person crew consisting of a UAS pilot, sensor operator, and spotter, along with a supervising thermographer were utilized to perform the inspection. The project started at first light to reduce down time associated with vehicle and pedestrian traffic, as well as the intense summer heat, which could hinder the aerial inspection. The Pilot-In-Command (PIC) held a Remote Pilot Certification as required by the FAA and managed the onsite operations. A safety brief was held by the PIC before initial takeoff, as well as throughout the day when necessary.

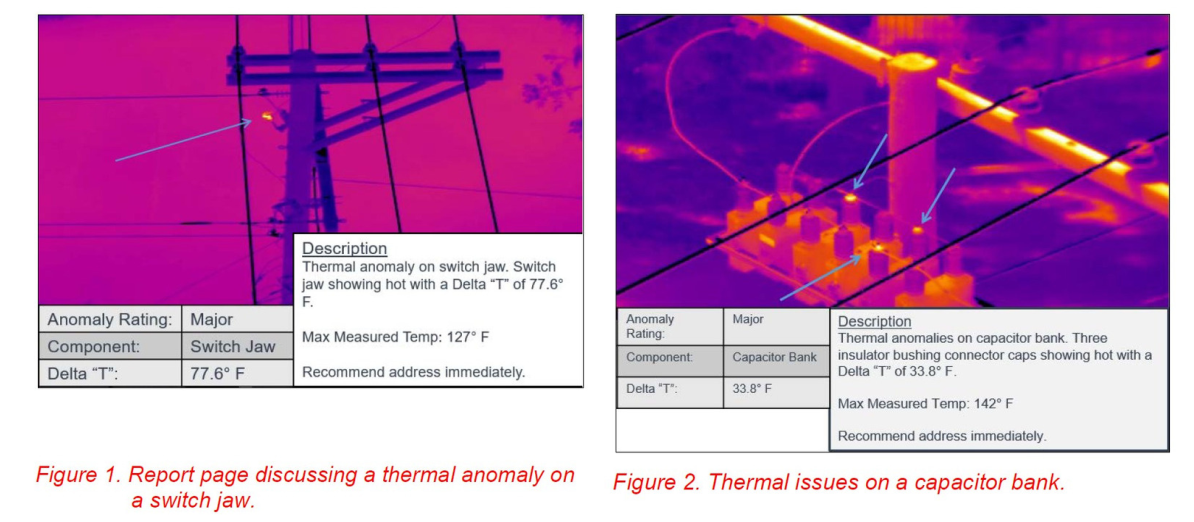

A Level II thermographer with substantial electrical inspection experience was onsite to identify anomalies of critical nature and provide guidance to the sensor operator. When critical thermal issues were identified in the field, the inspection team was able to immediately provide photographic evidence and location of the issue to the utility allowing them to plan and fully equip responders before mobilization to the site. Upon completion of the inspection, the data was reviewed and organized. Anomalies identified in the field were assessed and reported. A secondary review was performed to identify minor anomalies that may have been missed in the field. Utilizing the thermal camera’s fully radiometric imagery, the thermographer was able to review temperatures of the equipment for analysis and report deltas. A page by page report was created that included, but wasn’t limited to: type of anomaly, structure ID, criticality of the anomaly, and GPS coordinates of the aircraft, conductor load, and the time the photograph was taken.

All FAA guidelines were adhered to under part 107, which does not allow for flying over people or moving vehicles at any time. One of the spotter’s responsibilities was to identify oncoming vehicles, pedestrians, aircraft, and any other obstacles. If an obstacle was identified, the spotter’s directive was to immediately relay the necessary details to the Pilot-In-Command so appropriate action could be taken. The inspection crew was equipped with radios at all times (complying with regulations) during the inspection to facilitate efficient communication. Flying over the city streets was reduced to a minimum and appropriate signage was placed to alert oncoming vehicles of the inspection work. With this project taking place in the middle of an active community this posed several unique challenges. The problem of needing low-altitude thermal and visual photography along with the goal of not interrupting the daily traffic of the community was addressed by this means of inspection. As the inspection team, went from circuit to circuit, the operations center was notified, as well, to ensure locational awareness in case of incident.

CHALLENGES

UAS allowed the inspection to be performed within feet of one of the nation’s largest waterparks during peak summer operations. Tourism was at a high during the project and public safety was paramount to meeting client and public needs. Eliminating any interruptions to the flow of traffic was also of the utmost importance due to the heavy summer tourism. Another challenge faced was the summer heat, with temperatures climbing as high as 100 degrees during the week of the inspection. Care was taken to reduce the exposure of the crew to this heat by beginning the inspections at sunrise and ending the inspections early in the afternoon. Special care also had to be taken to reduce the exposure of the aircraft, sensors and flight tablets to the withering heat. Equipment, such as aircraft battery chargers, was shaded at all available opportunities to reduce their operating temperatures before being exposed to the elements again. It was noted that the equipment became less stable as the day progressed.

ADDING FUTURE VALUE TO ELECTRIC IMPROVEMENTS AND MAINTENANCE

The inspection was performed in the heart of downtown New Braunfels, TX without hindering traffic in any way. Helicopter acquisition would have to be performed at a very low altitude over dense residential and business areas, likely causing traffic issues and noise complaints. Any issue with the aircraft mid-flight might not be recoverable, and the safety concerns would be extreme. In comparison to traditional bucket truck inspections, SAM’s inspection time with the UAS was reduced by almost 10 times and was able to be performed without lane closures or traffic control. Ground based thermal inspections would be able to be performed at similar speed, but physical access would be needed for each pole and would not allow for an unimpeded aerial perspective.

The creativity provided by this partnership proved that utilizing UAS technology could reduce project time, the cost to the public for this type of work, increase the safety of the linemen and community, and reduce the probability for future outages; all without hindering normal public transportation and causing disruption to the community. The project garnered public media attention for its overall ingenuity but was also a focus for young students interested in the technology and how it can be parlayed into a career path.

The project met the needs of the utility and within the agreed upon costs. It was completed on time and provided numerous anomaly reports. The utility was able to dispatch personnel to the problem sites and make the necessary repairs to correct the issues. The utility’s linemen were able to review the report details and prepare for the repairs before arriving to the site. With the linemen understanding the problem before arrival, this allowed them to reduce their time in harm’s way, increasing their overall safety while focusing on the immediate problems and preventing potential outages.

CONCLUSION

By using a UAS aerial inspection solution, the utility reduced the amount of time needed by a substantial amount and was performed with less expensive equipment in about two and a half days, creating a tremendous cost savings to the client and the community. While SAM executed the inspection, the utility was engaged and contributed to the overall project development and inspection process. The utility assisted SAM in the development of processes, safety and notification procedures for acquiring the data from circuit to circuit, assisted in notifying the public of the use of UAS, and managed the community response and communications in coordination with SAM. The utility provided the community with advanced notice of the use of UAS in this populated area and provided them with a means of communicating concerns or complaints. At the end of the project, no complaints had yet to be received. The utility plans to continue to pioneer innovative strategies using advancing technology and is proud to be able to elevate industry standards by offering unconventional solutions to their clients.

SAM was awarded a Silver Medal in the 2018 ACEC Texas Engineering Excellence Awards for this project. Winning projects were selected based on uniqueness, originality, technical innovation, value to the engineering profession, complexity and how successfully the project met the needs of the client.