Furnace and Heater Tube Inspections

One of the more challenging applications of infrared thermography is in the measurement of process heater and furnace tubes. In fact, we get dozens of inquiries each year from our clients on this very subject. Quantitative thermography is the practice of measuring temperatures accurately and with furnace tubes this requires experience and knowledge. Success in this science is gained by being properly trained and certified as a Level I Furnace Inspection Thermographer. Certification training from the Infrared Training Center (http://www.infraredtraining.com) teaches you the techniques required for determining these values and will provide a complete understanding of temperature measurement and heat transfer.

Process Heaters

There are as many uses for process heaters as there are designs. The basic configuration consists of a shell (outer casing), tubes (where the process fluid flows) and a heat source. These units are both thermodynamically and hydraulically complex.

The simple drawing illustrates convective gas flow, which is turbulent, and radiant heat from the flame, refractory and other tubes – all non-uniform and time varying. When you view tube from an access port typically you can only see a portion of the tube or the tube at an oblique angle. Sometimes tubes are in rows, difficult if not impossible to image.

Tubes in a fired heater

Why are heater tubes of interest anyway?

There are several reasons for inspecting tubes. Qualitatively scale buildup on the outside of the tube can be readily identified. Buildup on the inside of the tube (coking) is a bit more difficult but commonly performed. In both cases the scale or coke prevents the transfer of heat into the process fluid. In the case of scale buildup, the process fluid may not be sufficiently heated, affecting downstream processing. The case of coking on the inside of the tube is more serious. Since the coke has an increased resistance to heat transfer, the tube surface temperature increases. After all it is the flow of the process fluid that is keeping the tube “cool” in the first place. The external tube surface, unable to conduct its heat to the water, increases dramatically, causing a failure (opening) in the tube. Metallurgists use the measured temperature to calculate the life of the tube so accurate measurements are critical

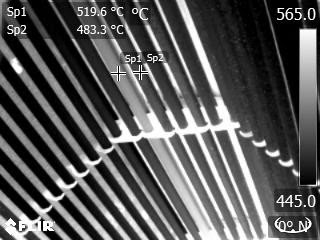

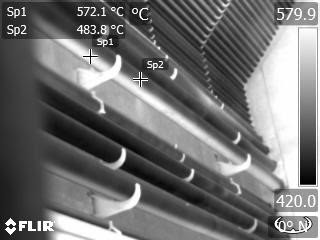

Sample Thermal Images

Tube with restricted flow

Coking on bottom of tube

Conclusion

IR offers the operators of process heaters the ability to visualize the heat transfer and provide vital temperature data to help determine remaining tube life. Certification training from the Infrared Training Center (http://www.infraredtraining.com) teaches you the techniques required to successfully implement this technology at your facility.